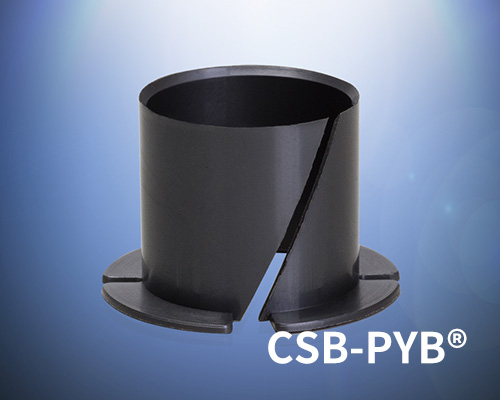

● Thin-walled plastic bearing for quick installation. It is made with CSB-EPB3M material wich is flexible for dimension viriation. Alternative material CSB-EPB7 is also available for special wear resistance requirement.

● Maintenance free, self-lubricated.

● Side groove designation for easy assembly.

● Groove design reserves the material expansion allowance.

● Suitable for rotation and sliding motions.

CSB-PYB® thin wall plastic bearing is designed with thinner wall comparing with the standard plastic bearing for those applications with small assembly spaces. Slipped gap ensures easy assembly of the bearings.

CSB-PYB® is also made from CSB-EPB3M material which is a good wear resistance polymer. The bearing self-lubricating performance is excellent for dry operation conditions. At the same time, continuous lubricating is allowed during the operation because this material is also with good isolation feature against the most common lubricants.

The spiral shape slip gap could not only make the bearing easy to be pressed into the metal housing, but also help to compensate any possible material expansion caused by the squeeze derived from the pressing. The recommended housing tolerance is H7 while the bearing could fit with the housing tolerance range up to H13. The bearing is allowed to be rotating in the housing after assembling.

4526

| Medium | PYB bearings resistance |

| Alcohol | Resistant |

| Hydrocarbons | Resistant |

| Greases. oils | Resistant |

| Fuels | Resistant |

| Diluted acids | Conditionally resistant |

| Strong acids | Not resistant |

| Diluted alkalis | Resistant |

| Strong alkalis | Conditionally resistant |

Please select bearing material and medium...

▊CSB® bearing material chemical resistance data is a comparison test result of the CSB chemistry laboratory using laboratory specimens or similar chemicals at room temperature 23 ℃, without considering the impact of other temperatures and chemical medium mixtures on the chemical resistance of CSB® bearing materials ; Therefore, this data can only act as a reference. CSB® recommends that the chemical resistance of actual parts should be tested under application conditions and verify the suitability of the bearings.

CSB® plastic bearings are highly wear-resistant plastic bushings, flange bearings and thrust washers made of composite materials. The working temperature CSB-EPB® plastic bearings up to 250 °C...

moreThe self-lubricated bearing is developed specially for the metal plate fitting. It is made with the CSB-EPB3M material which is good at shock absorbtion and wear resistance...

more● Clearance-free and preload design

● Adjustable fitting gap

● Maintenance-free

● Shock absorbing and no noise

Suitable for the application where the CSB® plastic clip bearing is hard to be located. The requirement of the fitting hole is not critical and the set screw could be secured without any risk of moving.

moreCSB® plastic wear resistance washer. Suitable for a fitting to the uncontrollable axial space in order to reduce the vabriation and noise during the operation.

moreWear resistance piston ring specially developed for the pneaumatic pump industrial application. It is easier to be installed comparing with the PTFE piston ring. Standard materials available are EPB13, EPB19 and so on.

more● Made of high anti-wear material EPB13;

● Maintenance-free, self lubricating;

● Chemical resistant;

● Dust resistant and quit running;

Self-lubricating, maintenance-free Low driving force Resistant to dust...

more