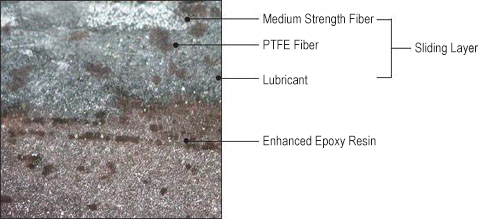

CSB-FWB® filament wound bearings use high-strength glass fiber and reinforced high-temperature resistant epoxy resin as the bearing layer, and special fiber and PTEF fiber as the sliding layer, which makes the bearing have excellent wear resistance and low coefficient of friction under high-load and low-speed working conditions. Under the condition of dry friction, CSB-FWB® bearings can exert good self-lubricating characteristics and high bearing specific pressure. CSB-FWB® filament wound bearing is the first prohibits lubrication sliding bearing product in China. CSB has developed a variety of self-lubricating bearings that can be adapted to different working conditions: CSB-CRM general-purpose wound bearings, CSB-CRB standard wound bearings, CSB-CRG high-load wound bearings, CSB-CRW underwater wound bearings, CSB -CRP high-speed wound bearings, CSB-CRF economical wound bearings, etc...

Among the CSB-FWB® filament wound bearings, CRM, CRB, CRG bearings are defined as "prohibited" lubricated bearings by CSB. After many tests, we found these bearings are easier to form a hard lubrication transfer film quickly under dry friction, while adding oil and grease will damage the self-made lubrication film. This makes the wear resistance of filament wound bearings under completely dry friction superior to under oil or grease lubrication .