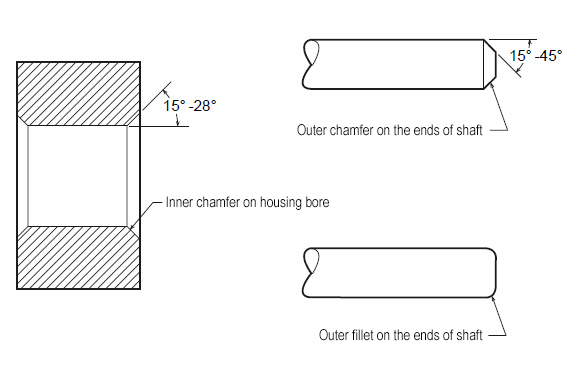

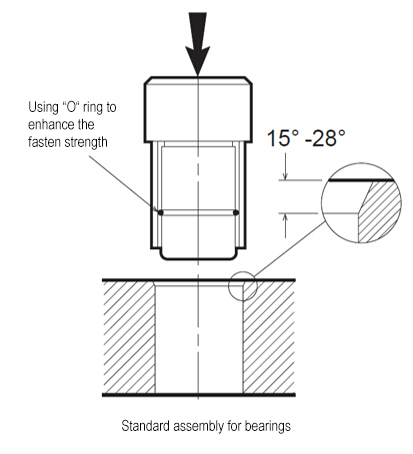

CSB-FWB® filament wound bearings are made of high strength PTFE fiber impregnated with high-temperature resistant and high strength epoxy resin. The bearings can withstand high strength, it is not allowed to withstand high impact loads. Therefore, it is not allowed to use hammer to hit the filament wound bearings during installation. We recommend using a press to press the bearing evenly into the housing bore with the guide angle. When the CSB filament wound bearing is pressed into the housing hole, the outer diameter of the bearing will expand to the entire cavity to achieve an interference fit state due to the elastic properties in the glass fiber base. When the wall thickness of the filament wound bearing is greater than 3mm, the shrinkage rate of the inner diameter after pressing into the housing can reach 1:1. Although the allowable value of the outer diameter compression of the filament wound bearing is 0.1~0.3mm, it will provide equipment manufacturers with more pressure installation methods by minimizing the interference degree of filament wound bearings.