The secret of CSB-FWB® filament wound bearings in high-load and oil-free operation is that it take advantage of the unique PTFE super fiber. The tensile strength of the PTFE super fiber is more than 20 times that of traditional PTFE resin, and it is not easily affected by cold fluid under high load. CSB-FWB® filament wound bearings use a film transfer process makes the bearings not require secondary lubrication during operation, even for start-up as well.

When the bearing start working, the PTFE filament of the filament wound bearing , is transferred from the inner surface of the bearing to the surface of the grinding shaft after a stage of change and wear and fills any defects existing on the shaft surface. In fact, a small part of the filament wound bearing is worn and coated on the grinding shaft to form a low-friction PTFE film. This wear is usually less than 0.03mm and can be ignored.

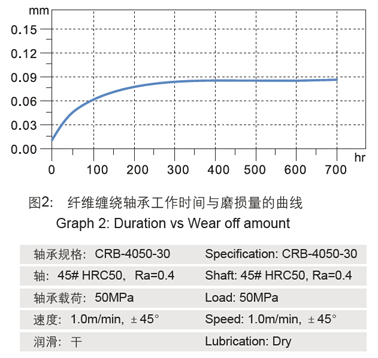

After the running-in period of the filament wound bearing, the wear rate gradually stabilizes and remains relatively constant throughout the service life. Therefore, the Filament wound bearing can maintain a minimum amount of wear during long-term operation with a very low friction coefficient under high load conditions. For example, CRB filament wound bearings were tested at a pressure of 50Mpa and a swing angle of 45°, the conclusion is that the wear of the bearing is about 0.09mm at 500,000 revolutions.

The time required for break-in is determined by PV (pressure and speed). Due to different working conditions, the average wear rate also varies. Specific factors include: load, speed, shaft hardness, material and shaft surface finish. To meet your specific application expectations, please contact CSB application engineers for more specific guidance on the break-in period.

Bearing wear depends on overall working conditions, such as speed, sliding distance and load. Under intermittent rotation or vibration, radial wear is negligible during thousands of hours of operation. The hard chrome coating has excellent wear resistance and prevents corrosion of the shaft. Chromium coatings, non-electric nickel coatings, YZD or nitrocarbide coatings are all commonly used surface treatment methods of shaft material that we recommend. This allows CSB-FWB® filament wound bearings to minimize bearing wear.