Engineering plastic bearings are applied in bottle washing machines of pharmaceutical machinery and play a very critical role which is an important part of the washing, filling and sealing interlocking machine group. The quality of the bottle washer directly affects the normal operation of the filling machine and sealing machine. The clamp of the bottle washer with self-lubricating bearings is the key part of the bottle washer. The clamps must ensure that the bottle can be accurately clamped and turned over every time, and have to be in a long-term contact with cleaning fluid. This requires that we must make sure the self-lubricating bearings can be long-term operation in the cleaning fluid and no inflexible rotation problems will happen, as well to make sure the bearings can work for a long time with accurate transmission and high wear resistance. EPB4 engineering plastic bearings have become the unique choice of manufacturers for rotating part of the bottle washer clamp with its excellent corrosion resistance and high wear resistance.

EPB4 engineering plastic bearings have excellent corrosion resistance, which uses self-lubricating materials that modified from the base material of high molecular polymers. Therefore, this bearing has extraordinary high corrosion resistance. The corrosion resistance of the bearings is still excellent even at temperatures up to 200℃.

EPB4 engineering plastic bearings have high wear resistance. EPB4 self-lubricating material uses high-strength polymer as the matrix material which further improves its comprehensive strength and the performance of pressure resistance and wear resistance. CSB applies polymer modification technology to implant reinforcing fibers and special wear-resistant compound in the matrix material. The CSB special underwater wear-resistant compound can ensure that the EPB bearing can exert its excellent self-lubricating performance even operating with water or completely immersed in the liquid. This ensures to lower the degrees of wear of the bearings and maintain the accuracy of the bearings during operation.

EPB4 engineering plastic bearings have very low water absorption. EPB4 self-lubricating materials are made of polymers with very low water absorption. The moisture absorption rate of EPB4 material is only 0.04% at RH50/23℃. In this case, the moisture content of the material is equivalent to the moisture content of general engineering plastics after circulating drying in a drying cabinet at 100℃ for 12 hours. This ensures that even if the EPB4 material is completely immersed in the solution for a very long time, it will not change the size of bearings because of water absorption or cause the stuck of bearings.

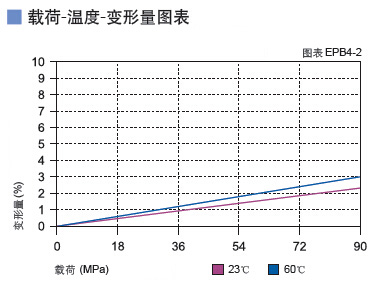

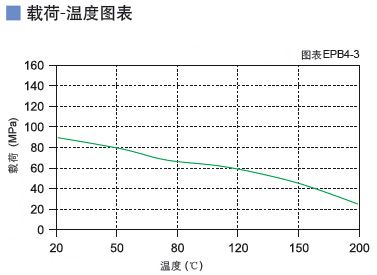

EPB4 engineering plastic bearings have excellent bearing capacity. It can withstand 90Mpa load at the temperature of 23°C, while the deformation of the bearing is only 2.3% under this limit load. It means that the bearings can work well under high loads. EPB4 bearings can still bear more than 20Mpa load at the temperature of 200°C, which is difficult to achieve the loading performance for general engineering plastic bearings.

EPB4 engineering plastic bearings do not have high requirements for matching shaft materials. Cold-rolled steel and carbon steel shafts are more suitable for rotary motion while stainless steel shafts perform particularly well in swing motion. When the load is lower than 5Mpa, chrome-plated hard shaft is a good option. The dry friction coefficient of EPB4 material is only 0.07~0.20 when using the shaft materials above. The friction coefficient can be below 0.12 applying with solution medium lubrication. It ensures EPB4 engineering plastic bearings to have superior self-lubricating properties than general engineering plastic bearings.

EPB4 engineering plastic bearings are widely used in pharmaceutical machinery and packaging machinery due to its excellent comprehensive performance. This bearing has excellent wear resistance, corrosion resistance, high-temperature resistance and good dimensional stability which is being favored by more and more designers.