Generally speaking, the tolerance of the thickness of the sheet metal material used in the car seat system and the tolerance of the punching holes are relatively large. However, a minimum clearance is required to reduce noise as much as possible in the seat system. In order to solve this problem, CSB developed and produced EPB3 engineering plastic bearings and PCB plastic clamp bearings. Nowadays, more and more car seat design engineers use CSB's plastic bearings.

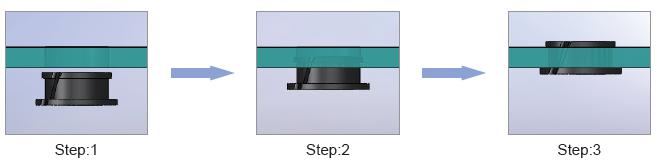

EPB3 engineering plastic bearings are made of high-quality engineering plastics as the basic raw material. High-strength fibers are added through polymer composite modification technology to further improve the compressive capacity of the matrix material. The special solid lubricant component is implanted into the plastic matrix material and fiber to meet the long-term oil-free lubrication working conditions. EPB3 engineering plastic bearings meet the abrasion resistance requirements of automotive seat adjustment mechanisms under high intensity operation by their excellent strength and wear resistance, and have passed the test of the 180-degree electrophoresis process, proving that there is no problem in actual application.The PCB plastic clamp bearing is made of EPB3M engineering plastic material. The structure of the PCB bearing adopts an open double flange design so that the inner and outer diameters of the bearing can be adjusted freely according to the actual size of the punching hole of the plate. It greatly reduces the manufacturing cost of the punching plate. The open design of PCB bearing makes the installation very easy. The PCB bearing can be directly installed by hand without any other auxiliary devices saving more manufacturing process costs. The double-flange design separates the two sides of the plate from other joint surfaces by wear-resistant materials, reducing the possibility of noise when adjusting the seat. Moreover, the double-flange design ensures that the bearings won’t be missing, whether in the transportation of semi-finished products or in the electrophoresis process.