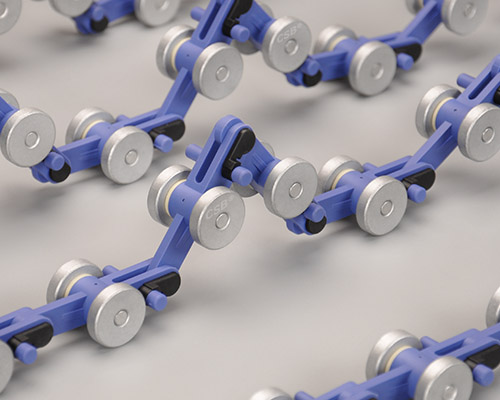

The rotation parts of PEC05 rotary chains are with self-lubricated plastic bearings, The plastic bearings made of EPB15 maintenance free materials, and with the anti-dust and anti-corrosion feature, The chain with easy to link or open design of the hinges, the chain system could be free to operate under critical conditions. The long term stable operation with low noise design of PEC05 chains prevent the chain system from stuck and operation failure comparing with the traditional rolling bearing design. The metal parts of the PEC05 chain are specially treated for the long term outdoor operation.

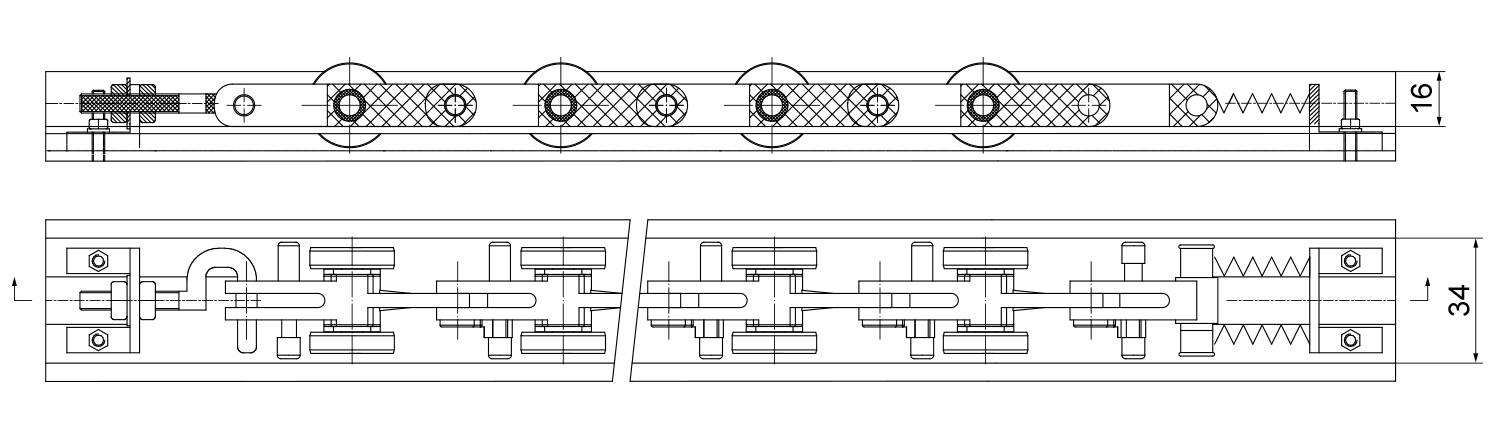

PEC05 technical data table

Part No. | Max. PV value[N/mm2*m/s] | Max. load [N/P] | Temperature [℃] | Max. speed [m/s] | Friction coefficient. | Break strength [N] |

PEC05 | 0.9 | 4320 | -40~100 | 1.0 | 0.05-0.20 | ≥1000 |

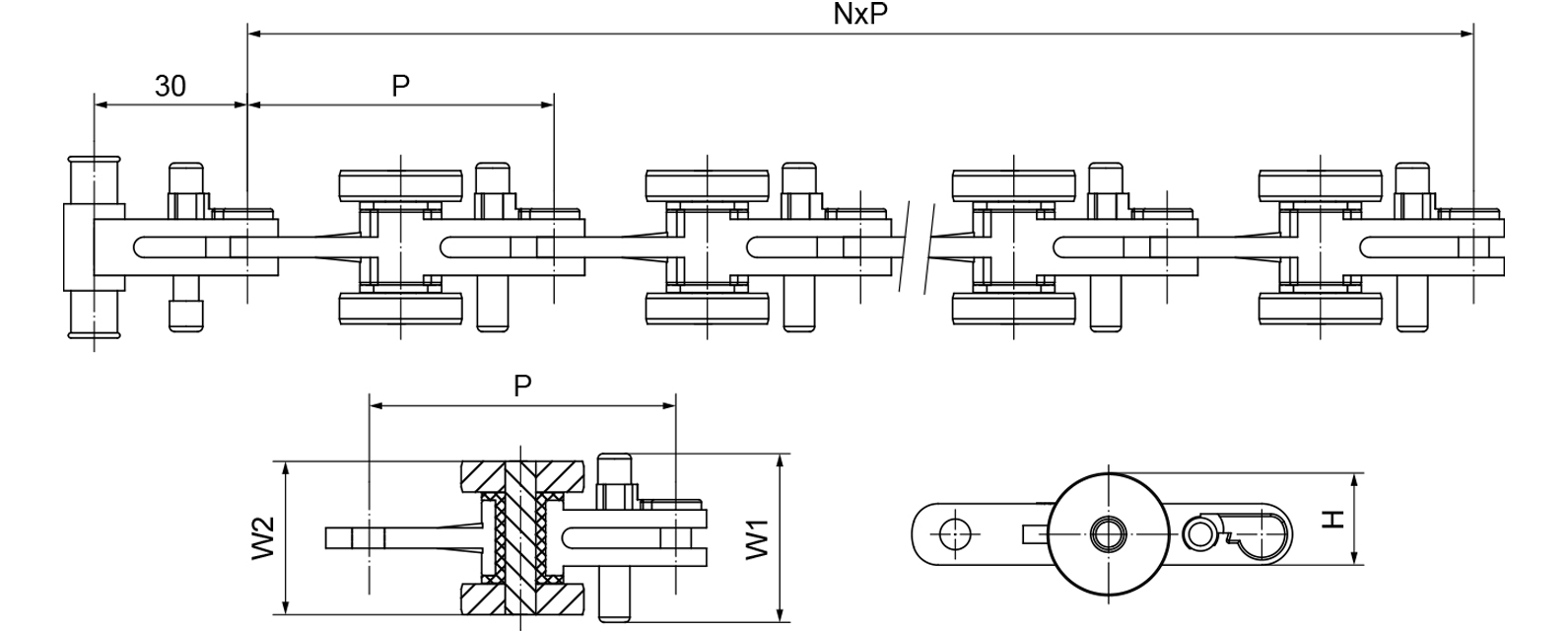

PEC05 standard specifications

| Part No. | P [mm] | W1 [mm] | W1 Tolerance [mm] | W2 | W2 Tolerance [mm] | H [mm] | N* [pcs] |

| PEC05-N* | 60 | 33.5 | ±0.15 | 30 | +0.30/0 | 18 | quantity |

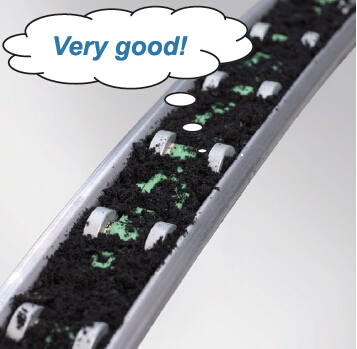

The design of the escalator rotary chain is usually with rolling bearings. There are a lot of containment and dust generated between the chain belt and the guide rail during the operation, therefore it induces damages to the rolling bearing and reduces the service life of the bearing and affects the performance of the bearing. Furthermore, outdoor operation of the escalator may cause corrosions to the rolling bearings. Under the above conditions, the rolling bearing in the chain is easy to cause failure of the operation of the chain. It may damage the chain system or consequently damage the driving motor in the escalator system.

The rotation parts of CSB-PEC® series rotary chain are with self-lubricated plastic bearings, the material CSB-EPB15 used in the plastic bearings provides maintenance free feature of the chain system and with the anti-dust and anti-corrosion feature of the bearing material, the chain system could be free to operate under critical conditions. The long term stable operation with low noise design of CSB-PEC® chain prevent the chain system from stuck and operation failure comparing with the traditional rolling bearing design. The metal parts of the CSB-PEC® chain are specially treated for the long term outdoor operation.

Good wear resistance and with low hardness and roughness requirement for the shaft material. The wear resistance of the material will not be weekend even under the dust environment.

moreCSB-EPB® Plastic plain bearings use high-performance plastics as the raw material, and filled high-strength fibers and special solid lubricants by the polymer compound technology to improve the anti-wear resistance...

moreDURARUB® backing material is high strength glass fiber with epoxy resin and the lubricating layer is PTFE filament and high strength fiber. The special structure performs an outstanding anti-wear feature and low friction…

moreDURAPLAS® self-lubricated plastic semi-finished products available service for the customer special requirement of uncommon bearings. It is possible for the mold cost saving and improves the delivery time...

moreCSB® metal sliding bearings suitable for low-speed and heavy load, intermittent operation and swing condition...

moreDURAMOV® cable chains are made of high strength and anti-wear plastics, The cable chains are used in a variety of motion modes and strokes. DURAMOV® cable chains can carry FLEXMOV® flexible cables and energy hoses...

moreThe rotation parts of PEC03 rotary chains are with self-lubricated plastic bearings, the material CSB-EPB15 used in the plastic bearings provides maintenance free feature of the chain system...

more