DURAMOV® cable chains are made of high strength and anti-wear plastics, The cable chains are used in a variety of motion modes and strokes. DURAMOV® cable chains can carry FLEXMOV® flexible cables and energy hoses, such as control cables, data cables, servo cables, motor cables, bus cables, robot cables, oil and gas hoses...

Small pitch for low-noise, smooth running, One-piece design, non-openable

Inner height: 07 to 15mm

Inner width: 07 to 50mm

Small pitch for low-noise, smooth running, One-piece and open design

Inner height: 05 to 10mm

Inner width: 05 to 30mm

Small pitch for low-noise, smooth running, Two-pieces design, openable along the outer radius

Inner height: 15 to 20mm

Inner width: 16 to 50mm

Small pitch for low-noise, smooth running, Two-pieces design, openable along the inner or outer radius

Inner height: 10 to 20mm

Inner width: 10 to 50mm

Openable along inner or outer radius from both sides, large pin/bore and crossbar with high locking force

Inner height: 18 to 45mm

Inner width: 38 to 175mm

High strength and stable, long service life, openable along the both sides

Inner height: 32 to 80mm

Inner width: 50 to 200mm

Special crossbar design for multiple inner width, High strength and stable, openable along the both sides

Inner height: 32 to 80mm

Inner width: 200 to 600mm

Elastic connection and small pitch for low-noise, smooth running, openable along the both sides

Inner height: 28mm

Inner width: 30 to 60mm

Low-noise and smooth running, openable along the both sides, for cleanroom and high-speed applications

Inner height: 29 to 52mm

Inner width: 40 to 150mm

Electro-Static discharge, surface resistance <109Ω, One-piece design, non-openable

Inner height: 07 to 15mm

Inner width: 07 to 50mm

Electro-Static discharge,Surface resistance <109Ω, Two-pieces design, openable along the outer radius

Inner height: 15 to 20mm

Inner width: 16 to 50mm

Electro-Static discharge,Surface resistance <109Ω, Two-pieces design, openable along the inner or outer radius

Inner height: 10 to 20mm

Inner width: 10 to 50mm

Electro-Static discharge,Surface resistance <109Ω, Openable along inner or outer radius from both sides

Inner height: 18 to 45mm

Inner width: 38 to 175mm

● very stable and rugged for heavy machinery

● Two piece design, adjustable to the width according the cable chains

● Available in galvanised steel and stainless steel

DURAMOV® plastic cable carrier accessories including: stress relief unit and C-shaped bracket; vertical separator and horizontal separator ...

BL bellows is suitable for use in general mechanical applications, The good anti-freezing ability and self-extinguishing properties can be used in automotive industries. The bellows keep high impact resistance in ...

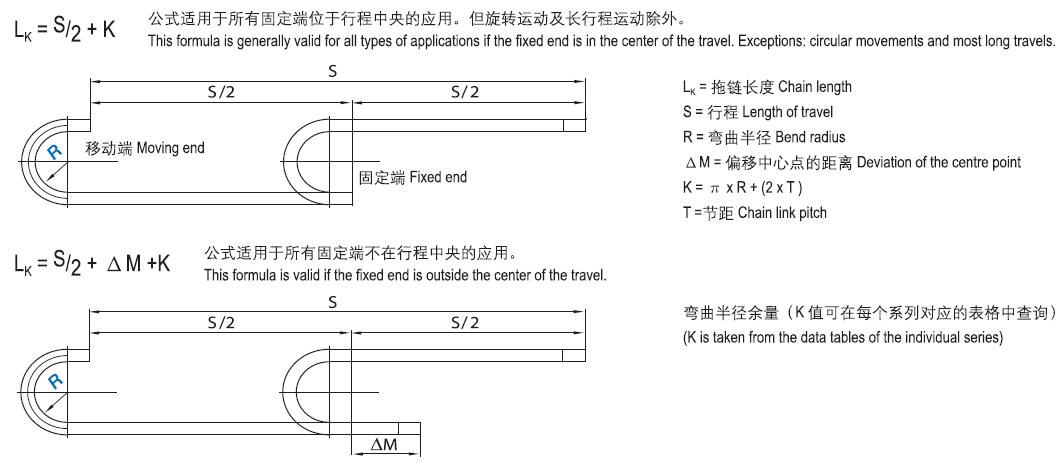

The fixed end in the center of the travel is the most costeffective solution.

The chain length LK is calculated by using half the length of travel and adding the value K if the fi xed end of the chain is located in the center of the

travel, You can get the value K from the size table in every series chain. It is the most cost-effective solution if Placing the fi xed end in the center of

the travel, Because it requires the shortest chain, cables and hoses.

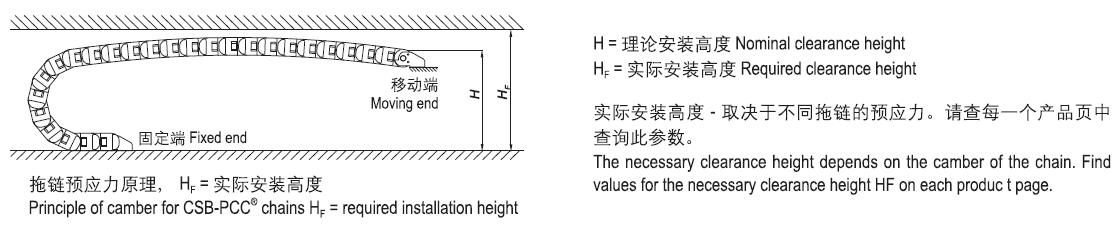

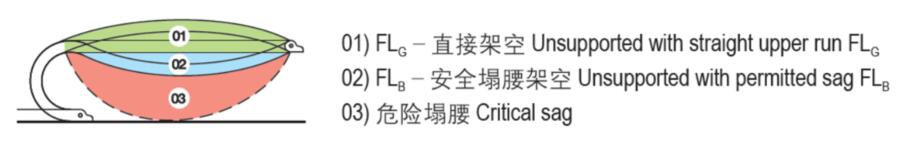

The largest possible unsupported length is influenced by the design, material and camber. Camber is the curve of the upper run along its unsupported length. All DURAMOV® chains are manufactured with camber. In the Installation dimensions section of each respective chain description, you will fi nd the measurement HF, which specifi es the necessary clearance height, taking the camber into account. The camber allows for longer unsupported lengths and increases service life and operating safety. Upon request, we can deliver chains without camber for restricted space applications - however, these no camber chains do not have the same load-bearing capacity.

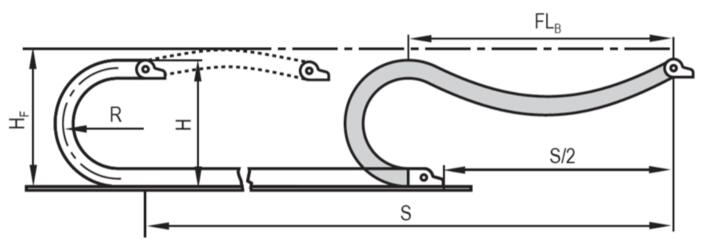

If the upper run of the cable chain operates without touching the lower run over the entire travel, it is called an unsupported application. The distance between moving end and the beginning of the radius curve of the is called the unsupported length. The unsupported application is the most common. DURAMOV® chains are very well suited for high dynamics and long service life. The maximum unsupported length depends on the fi ll weight and the type of the cable chain or tube. As a result, we differentiate among three types of unsupported length.

The cable chain is unsupported FLG when the upper run still has camber, is straight or has a maximum sag of 1/2 of the chain link height. Installing the chain in FLG is always recommended. The runs smoothly without additional vibration.

The FLG type of installation always generates the longest service life and can be operated with the max. values for speed and acceleration.

The cable chain is unsupported FLB when the sag is more than 1/2 Chain link height and less than the smallest available radius of this DURAMOV® series. In most applications the can be used unsupported FLB without any problems. There are restrictions concerning the maximum speed and acceleration.

The FLG type of installation always generates the longest service life and can be operated with the max. values for speed and acceleration.

When the sag of the cable chain is higher than allowed for FLB, it is in critical sag. Using an cable chain in critical sag should be avoided or solved with special solutions. An cable chain should never be installed with critical sag. Applications may reach critical sag after long service times. The cable chain or tube should be replaced in these cases.

For hanging applications, heights of over 100m are possible with DURAMOV®. Particularly in the area of material fl ow technology, the cable chain enables a bundled supply of a wide variety of cable types. The use of an cable chain ensures that individual cables are not entangled in parts of shelves or protruding pallets. We recommend locking mounting brackets for vertical hanging applications.

Two important factors in vertical hanging applications are how the cables and hoses lay in the cable chains and and how they are secured at the end points: all cables and hoses must be hung so that they bear their own weight. The chain the chain fulfi ls the function of orderly conduit bundling only and should not absorb any further tensile forces. The chain interior separation elements should be used for distinct division of all cables and hoses. The cables and hoses must be secured carefully to both end points of the chain. The strain relief must be designed so that the opposite run cannot catch. Safe strain relief and clear separation of the cables and hoses are the basic prerequisites for hanging installations. Cables must be able to move freely and bear their own weight.

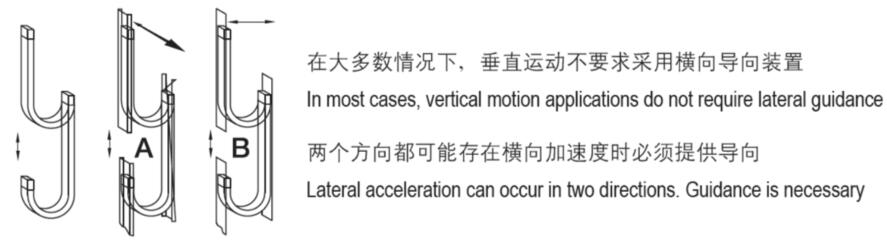

If the application has a purely vertical movement without lateral acceleration, a lateral support is not necessary. If lateral acceleration occurs, lateral guidance of the chain must be provided in most cases. The diagram shows the principle of such guidance. Partial guidance is also an option however, it must at least cover the area in which the chain may sway. Lateral acceleration can occur in two directions. The lateral guidance must be installed accordingly. If you have a choice, the layout in fi gure A is preferred. The lateral acceleration then acts transversely to the chain, where it is more stable. When using a guide, an chain with camber should be selected. This ensures that the chain is pressed into the trough.

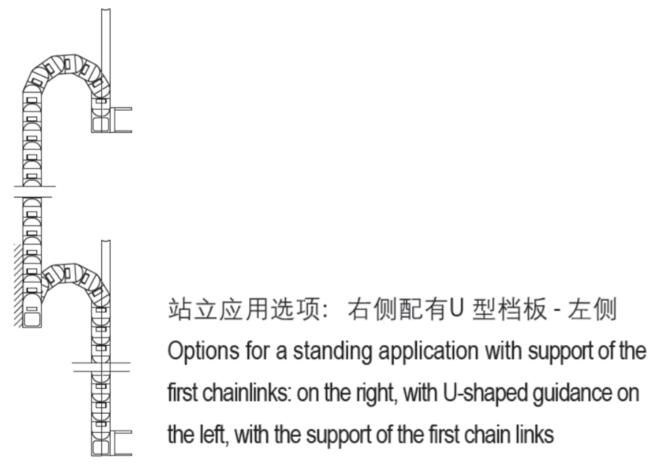

Standing applications are standard on many machines and plants. Cables will be guided safely in vertical strokes.

The mounting brackets must be attached so that the cable chain cannot bow outwards. Locking mounting brackets are highly recommended because they can be attached fl ush to the machine.

Cables and hoses must be laid in the chain so that they can bend freely and bear their own weight. For precise guidance of the cables and hoses, we strongly recommend interior separation elements. Cables must be strain relieved at both ends.

If lateral acceleration occurs, the cable chain should, in most cases, be supported along the outer radius. For higher chain heights, it is generally recommended that at least the first three links on the outer radius be supported. For maximum heights and weights, the whole distance must often be supported. Due to the wide variety of combinations involving fi ll weights, stroke heights, chain types and bend radius, we recommend you contact with us.

DURAMOV® cable chains placed on their side can be used unsupported to a limited extent. The turned unsupported length in this case is dependent on the following factors:

1、Fill weight

2、Width of the chain

3、Bend radius

4、Parallel placement

We recommend locking mounting brackets for sidemounted applications

The greater the fi ll weight of the chain, the shorter the available unsupported length. When placed on its side, the chain width, in effect, becomes the height. As this height increases, the cable chain becomes proportionally more stable. If further movement in a second axis is added to the parallel motion of two chains, the unsupported length is impaired. For applications with low fi ll weight, the standard mounting chain is supported brackets are adequate. If, however, the fi ll weight is high and the travels are long, the chain must then be supported either in whole or in part. Due to the variety of application possibilities, we strongly recommend you make use of our consulting services.

Side-mounted chains are strongly recommended if the installation height is restricted.

Standard values for unsupported lengths, side-mounted, upon request. The unsupported lengths can be extended by supporting the links next to the mounting brackets.

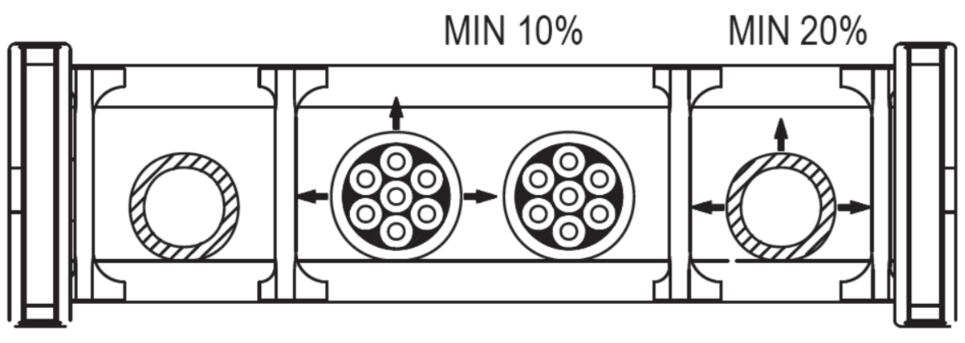

In order to ensure that the cable chain is functioning properly and to avoid damage to the cables or hoses, the following principles must be observed when laying cables or hoses:

| ▊ This minimum clearance would be 10% for electrical round cables, 20% for hydraulic hoses. |

| ▊ In order to reduce the possible friction, avoid pipes with different skin materials such as cables or hoses.(eg: cable and hydraulic hoses) |

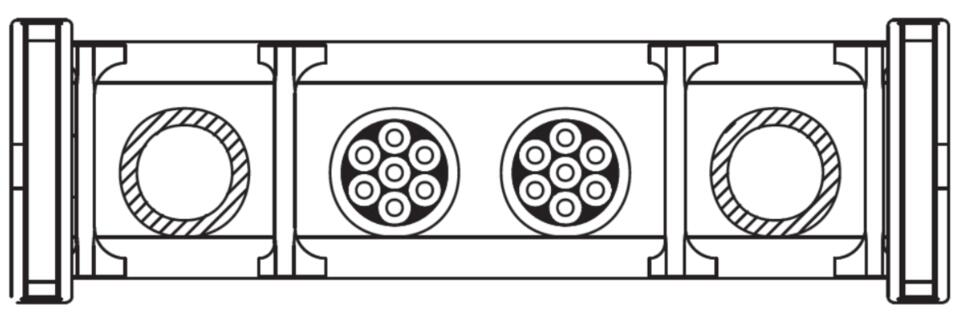

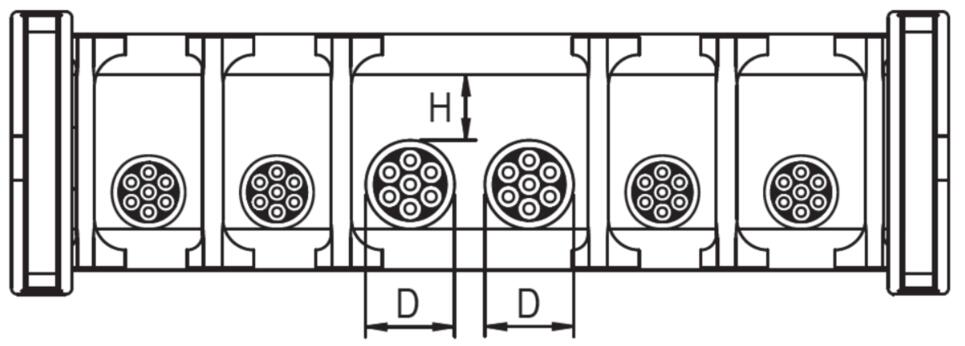

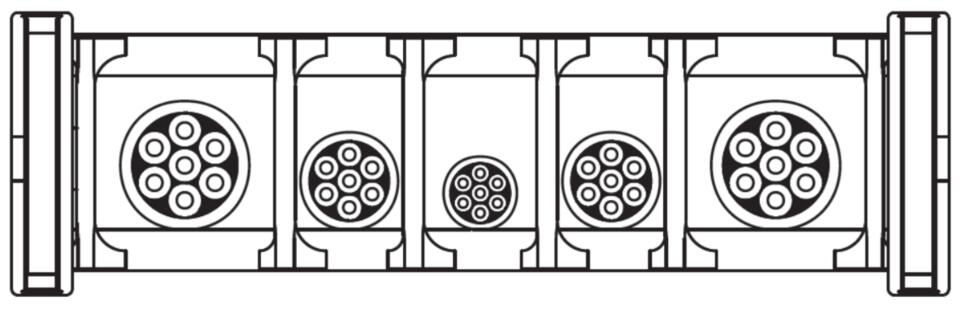

| ▊ In applications where multiple cables and hoses are used, in order to avoid mutual friction between them, it is preferable to place them in a suitable separate space and separate them from each other with a spacer. If there are no conditions to achieve, make sure there is enough space between them to avoid mutual friction (H<D). |

| ▊ The cables or hoses are laid in a symmetrical manner according to their diameter and weight. The largest and heaviest cables are placed on the outside of the section and the small and light cables are placed on the inside. |

The DURAMOV® guarantee is valid within 36 months from the date of delivery.

A guarantee claim is deemed to exist if the DURAMOV® cable chain supplied is demonstrably not free from material and manufacturing defects.

In concrete terms, this means that the DURAMOV® cable chain wears out before the end of the guarantee period due to wear and tear during normal use.

The guarantee claim expires in the event of mechanical damage and damage caused by incorrect installation or improper use of the cable chains.

The guarantee is valid for new purchases as of 01/06/2021, starting with the delivery date of the DURAMOV® cable chains.

The guarantee ends at the end of 36 months period, starting from the date of delivery.

For the given guarantee period, CSB provides a free replacement (delivery ex works). This applies only to CSB DURAMOV® components that fail due to wear and tear.

Shipping of replacement parts does not extend the guarantee period.

The FLEXMOV® flexible cables used in the e-chain also come with a guarantee of up to 36 months.

The DURAMOV® guarantee is valid around the world..

In the event of a guarantee claim, please contact our sales team, who will be happy to take care of your request.

CSB conducts approximately 10 million DURAMOV® cable chain endurance tests at 68 laboratory stations and more than 30 application stations every year. The cable chain test laboratory includes different installation and application tests: short-stroke unsupported installation, vertical hanging, vertical standing, side-mounted and long-stroke sliding tests in outdoor natural climates; The cable chain application station tests include: Application tests of C02 cable chains on machining centers, Application tests of C02 and C06 cable chains on grabbing manipulators or robots, Application tests of C03 cable chains on long-stroke manipulators, Application tests of micro cable chains such as C01 and C31 on high-frequency motion devices...

DURAMOV® cable chains undergo durability testing for robot applications and long-stroke drag and slide applications in a precision shaft production workshop in Anhui, China. C02.25 cable chain is mainly used in the Z-axis and Y-axis of the manipulator, and C03.42 cable chain is mainly used in the long-stroke moving area of the manipulator; the lateral travel about 25 meters, and it performs more than 2,000 cycles every day, and the grabbing movements over 4000 cycles; DURAMOV® cable chain ensures 24-hour trouble-free operation of the automatic production line...

▊DURAMOV® Cable Chain Finder[V1.1] is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations filler and installation data by entering parameters such as cables, gas tubes, oil tubes and installation data, The system will analyze your design data and finally output the adaptation cable chains.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the cable chains must be tested again to verify whether it meets the actual use requirements.

▊DURAMOV® Cable Chain Finder output data information is only for design reference, and can not be used as the final standard for determining the cable chains conformity, If you have any questions, please contact CSB® sales engineers.

▊FLEXMOV® High-flexible Cable Finder V1.0 is based on a large amount of test data from CSB® laboratories and combined analysis and calculation of cable materials and structural characteristics. You can find suitable cables by selecting sheath materials, cable application parameters and application environment options, and combined with the cable core wire and shielding requirements, the system will output an adapted flexible cable.

▊Since the system's simulation calculation analysis based on theoretical data may not fully meet the input parameters, data verification has certain limitations; CSB® recommends that flexible cables need to be tested and verified again on the equipment to fully meet the actual use requirements.

▊The output data information of the FLEXMOV® high-flexible cable finder is only for reference in design selection and cannot be used as the basis for final cable compliance determination; if you have any questions, please contact CSB® sales engineers.

CSB-LIN® maintenance free plastic linear bearings. Low noise operation is suitable for continuously applications under the extremely dusty environment. It is washable by the clean detergent of the food machine …

moreCSB-BAL® plastic spherical bearing for self-aligning solution. The spherical ball is made of wear-resistant composite material and the housing material is made of fiber-reinforced high-strength composite material....

moreCSB-LIN® Linear guide rails & Screw nuts designed with the maintenance-free sliding conponents. All sliding parts are made of wear-resistant material CSB-EPB®. resistant to dust, anti-corrosion and low noise.

moreCSB-SRB® slewing ring bearings are made of self-lubricating materials as the sliding units,Smooth operation and no noise, High-speed operation and long life, Operation temperature ±200℃…

moreHigh flexible cables are designed for highly bending and continuous motion applications and used for cable chains, robots, auto-drive systems, etc ...

moreCSB automation technology is based on maintenance free sliding friction as a motion pair to achieve maintenance free, low noise, longer service life, and lightweight design of automation module components and robots...