FLEXMOV® High flexible cables are designed for highly bending and continuous motion applications and used for DURAMOV® cable chains, robots, auto-drive systems, etc.

● Available outer jacket materials: PVC, PUR, TPE

● Overall shield or unshielded cables are available

● Silicone-free and oil-resistance

● Halogen-free and Hydrolysis-resistance

● UV-resistance and Flame retardant

● For highly flexible control cables in cable chain

● Outer jacket materials: PVC, PUR, TPE

● Shielded and unshielded cables are available

● Operating temperature: -55/+100℃

● For highly flexible data cables in cable chain

● Outer jacket materials: PVC, PUR, TPE

● Shielded data cables

● Operating temperature: -55/+100℃

● For highly flexible bus cables in cable carriers

● Outer jacket materials: PVC, PUR, TPE

● Shielded and flame-retardant bus cables

● Operating temperature: -50/+70℃

● For highly flexible motor cables in cable chain

● Outer jacket materials: PVC, TPE

● Shielded and unshielded cables available

● Operating temperature: -55/+90℃

● For highly flexible servo cables in cable chain

● Outer jacket materials: PVC, PUR

● Shielded and flame-retardant servo cables

● Operating temperature: -50/+80℃

● For highly flexible measuring cables in cable chain

● Outer jacket materials: PVC, PUR

● Shielded measuring system cables

● Operating temperature: -55/+90℃

Flexible cables include control cables, data cables, bus cables,motor cables, robot cables, servo cables, measurement system cables, etc.

Control cables are common cables in the automation industry. High-frequency, long-term movements require control cables to maintain good wear resistance and mechanical properties in the cable chain.

Data cables Continuous movement within the cable chain requires extremely high EMC shielding requirements for cables, so the data cable needs to have special EMC protection requirements. In order to ensure that the data cable does not affect data transmission during the long-term bending movement of the cable chain, reliable structural design and The production process, especially the shielding layer.

Bus cables The rapid development of Ethernet communications in the industrial field has placed extremely high requirements on the design and production of fieldbus cables. This is the only way to avoid mechanical damage to the cable during operation and signal loss during data transmission. Damage to the shielding layer and changes in characteristic wave impedance will increase the attenuation, which will lead to a sharp drop in the data transmission rate. Since the attenuation value will continue to change during the movement of the cable, troubleshooting becomes very difficult.

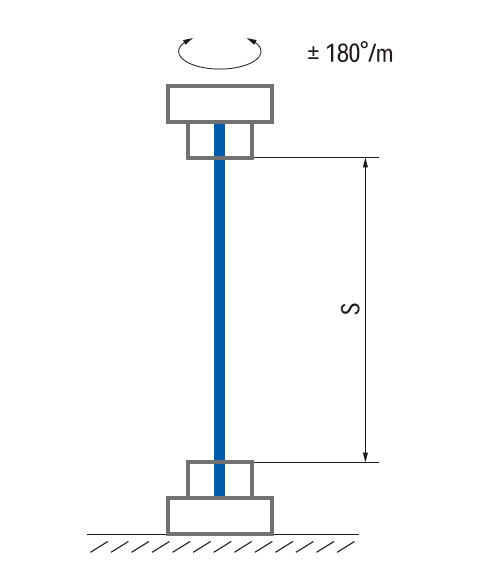

Robot cables used for torsional movements are subject to very specific stresses. In the case of shielded bus cables, the insulation and shielding are subject to high mechanical stress during bending and torsional movements. This requires a completely different structural design concept for robot cables than for linear movements.

Servo cable are standard accessories in drive technology and are commonly used in automation technology and mechanical structures. Due to the combination of power core wires and shielded pairs, the mechanical structure of the servo cable is always very unbalanced. In order to ensure that this asymmetry does not cause cable damage during operation in the drag chain, the servo cable must have a very special design, especially for long-distance gliding. As the speed of today's ICBT inverters continues to increase, low-capacitance insulating materials have become more important.

Motor cables are common accessories in drive technology and are used in automation technology and mechanical structures. As today's sports requirements are getting higher and higher, in order to ensure that power cables can operate safely and stably for millions of times, the cables need to have special conductors, insulation and core wire stranding designs. As the speed of today's IGBT inverters continues to increase, low-capacitance insulating materials have become crucial.

Measurement System Cables are important communication components connecting the drive and control systems. If there is no safe and timely feedback of electronic signals during movement, damage to the equipment may occur. Therefore, measurement system cables have special requirements for EMC protection. If there is continuous movement within the energy chain, the EMC shielding will be severely tested by mechanical stress. In order to ensure that these stresses do not cause failure of the measurement system, reliable structural design is very important, especially for shielding and stranded structures.

● Special short pitch bundled stranding

● With an intermediate layer to ensure that the insulation layer and sheathing layer are bonded and damaged

● Shielded cables with fully extruded inner sheath

● The shielding layer with optimized braiding angle ensures the highest EMC protection

● The fully extruded outer sheath ensures the stability of the shielding layer and the twisted structure

● The insulation material used will not change the insulation properties of the cable even after millions of operations

▊Test methods | Fire tests

| Test | Specification | Design |

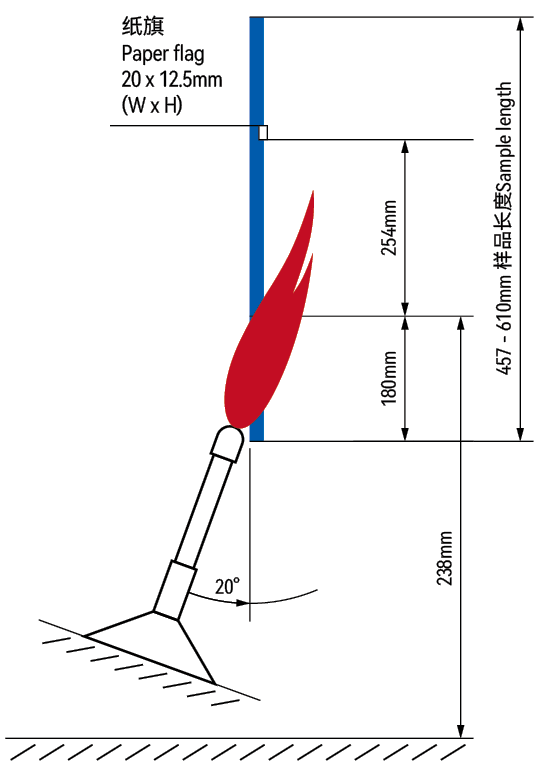

| Vertical Flame and FT1 | UL 1581, § 1060 (Vertical Flame and FT1 Test) Length of the sample: 457mm-610mm Burner: Bunsen burner with additional air supply(Tirril gas burner) Ø9.5mm Test temperature: 500 W flame Position of the sample: Vertical Position of the flame: 20° to the vertical Flame duration: 5 x 15 seconds with 15 seconds flame break each Conditions: - Paper flag up to maximum 25% charred - The sample must continue to burn for maximum 1 minute |  |

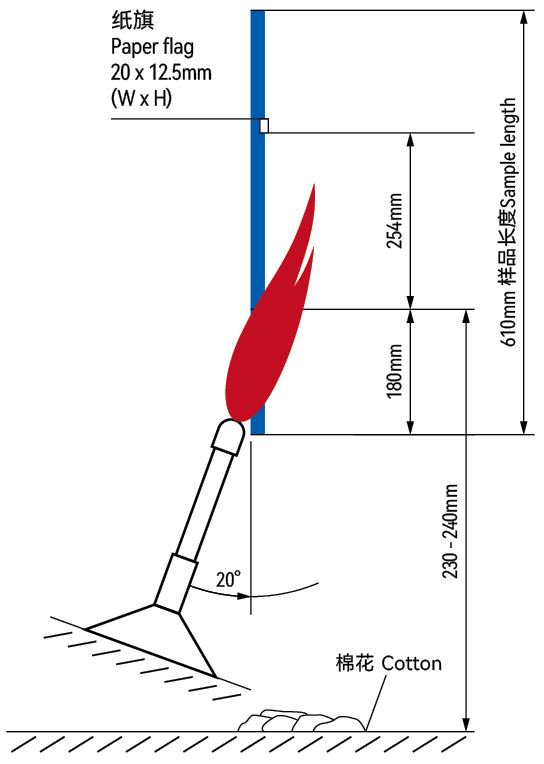

| VW-1 Flame | UL 1581, § 1080 (VW-1 Flame Test) Length of the sample: 610mm Burner: Bunsen burner with additional air supply (Tirril gas burner) Ø9.5mm Test temperature: 500 W flame Position of the sample: Vertical Position of the flame: 20° to the vertical Flame duration: 5 x 15 seconds with 15 seconds flame break each Conditions: - Paper flag up to maximum 25% charred - The sample must continue to burn for maximum 1 minute - Time noted until the flame/sample is extinguished - Dripping material must not ignite the cotton lying under it |  |

▊Test methods | Media tests

| Test | Specification | Design |

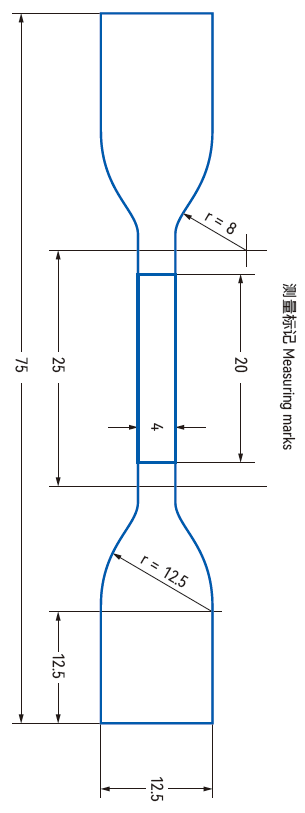

| EN 50363-4-1 | Testing of oil resistance for PVC jackets Test according to EN 60811-2-1, Clause 10 Test oil: IRM 902 Preparation of the sample according to EN 60811-501 Test temperature: 90±2° Test duration: 7x 24hrs Followed by storage at room temperature of at least 16hrs, but not longer than 24hrs Maximum alteration of tensile strength: ±30% Maximum elongation at break: ±30% |  |

| EN 50363-10-2 | Testing of oil resistance for PUR jackets Test according to EN 60811-2-1, Clause 10 Test oil: IRM 902 Preparation of the sample according to EN 60811-501 Test temperature: 100±2° Test duration: 7x 24hrs Followed by storage at room temperature of at least 16hrs, but not longer than 24hrs Maximum alteration of tensile strength: ±40% Minimum median elongation at break: 300% Maximum elongation at break: ±30% | |

| EN 60811-404 | Testing of oil resistance for TPE jackets Test according to EN 60811-2-1, Clause 10 Test oil: IRM 902 Preparation of the sample according to EN 60811-501 Test temperature: 100±2° Test duration: 7x 24hrs Followed by storage at room temperature of at least 16hrs, but not longer than 24hrs Maximum alteration of tensile strength: ±30% Maximum elongation at break: ±30% |

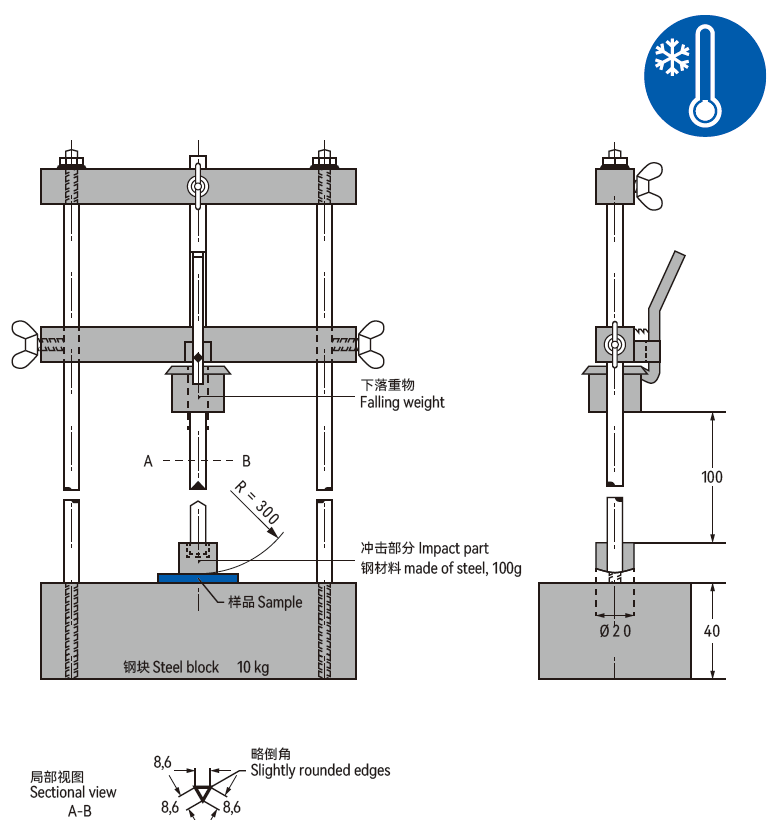

▊Test methods | Low temperature tests

| Test | Specification | Design |

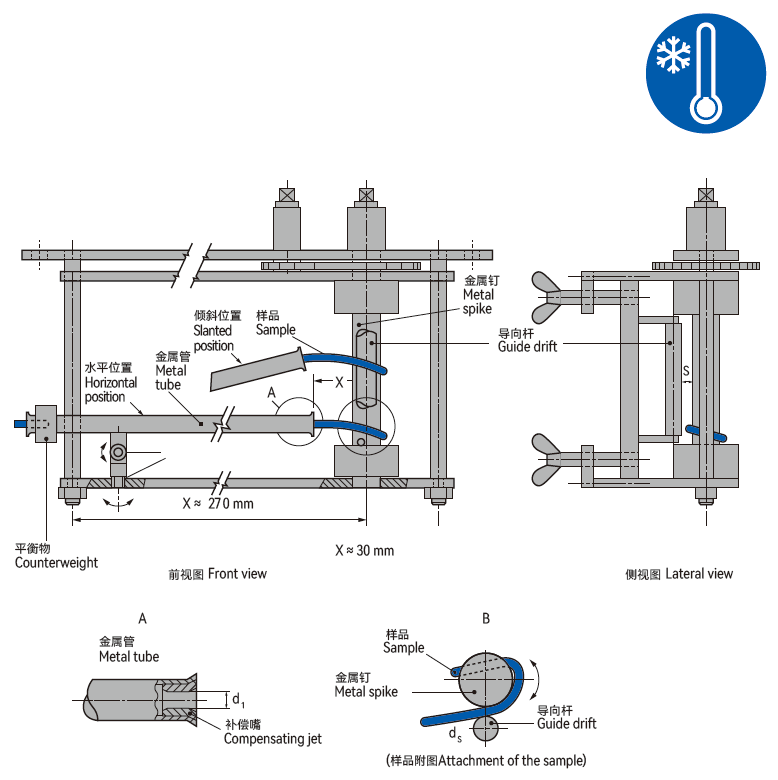

| EN 60811-504 | Bending test at low temperature for jacket Feed-through of the cold winding test according to 8.2 from EN 60811-504 Deviating from the standard also the outer diameter of the sample > 12.5mm Mandrel diameter 4-5 times the sample diameter (there must be at least 2 samples)

Storage of the wound sample > 16hrs at test temperature Heat to room temperature When viewed with the naked eye or visual aid without magnification, there should not be any cracks in the outer jacket |  |

| EN 50305 | Low temperature impact test for jacket Feed-through of the cold impact test according to 8.5 from EN 60811-504 Selection criteria according to 5.1 from EN 50305

3 pieces, length at least 5x the outer diameter or 150mm Storage of the wound sample > 16hrs at test temperature Heat to room temperature When viewed with the naked eye or visual aid without magnification, there should not be any cracks in the outer jacket |  |

▊Test methods | Motion tests

| Test | Specification | Design |

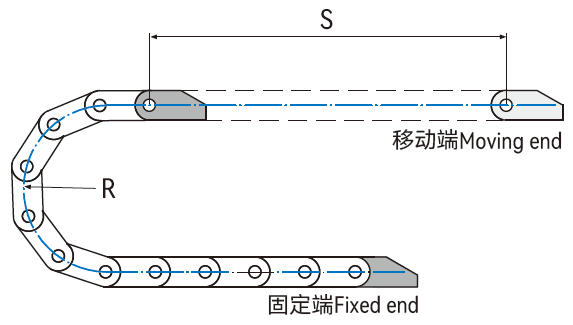

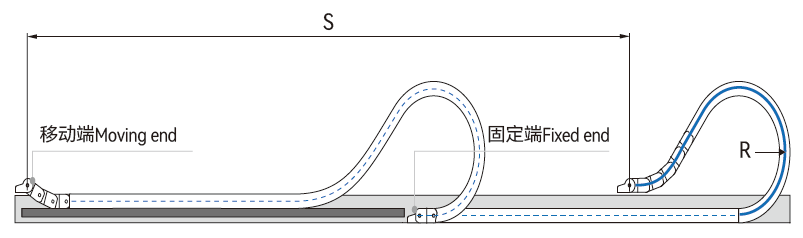

CSB® test: "Short travel" in DURAMOV® | Horizontal travel Travel length S: up to about 2m Temperature: approx. from -5°C to +35°C Bending factor: according to the catalogue (approx. 5 – 7.5 x d) Target: minimum 5,000,000 double strokes |  |

CSB® test: "Long travel" in DURAMOV® | Horizontal travel Travel length S: up to about 20m Temperature: approx. from -10°C to +40°C Bending factor: according to the catalogue (approx. 5 – 7.5 x d) Target: minimum 5,000,000 double strokes |  |

CSB® test: "Torsion test" | Twisted length S: about 1m Rotation angle: according to catalogue (about ±180°) Target: minimum 5,000,000 cycles |  |

The FLEXMOV® guarantee is valid within the number of double cycles specified by CSB or within 36 months from the date of delivery, whichever comes first.

A guarantee claim is deemed to exist if the FLEXMOV® cable supplied is demonstrably not free from material and manufacturing defects.

In concrete terms, this means that the FLEXMOV® cable wears out before the end of the guarantee period or the guaranteed number of double strokes due to natural wear and tear during normal use.

The guarantee claim expires in the event of mechanical damage and damage caused by incorrect installation or improper use of the cable.

The guarantee is valid for new purchases as of 01/07/2021, starting with the delivery date of FLEXMOV® flexibe cables.

The guarantee ends at the end of 36 months period, starting from the date of delivery.

For the given guarantee period, CSB provides a free replacement (delivery ex works). This applies only to CSB FLEXMOV® components that fail due to wear and tear.

Shipping of replacement parts does not extend the guarantee period.

We also offer a guarantee of up to 36 months on the DURAMOV® cable chains used.

The FLEXMOV® guarantee is valid around the world..

In the event of a guarantee claim, please contact our sales team, who will be happy to take care of your request.

About 100 million cable cycle durability tests are conducted in the CSB laboratory every year. Different cable application tests are conducted in the CSB laboratory every day, providing verification data and long-term life guarantee for different applications of FLEXMOV® high-flexible cables...

▊DURAMOV® Cable Chain Finder[V1.1] is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations filler and installation data by entering parameters such as cables, gas tubes, oil tubes and installation data, The system will analyze your design data and finally output the adaptation cable chains.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the cable chains must be tested again to verify whether it meets the actual use requirements.

▊DURAMOV® Cable Chain Finder output data information is only for design reference, and can not be used as the final standard for determining the cable chains conformity, If you have any questions, please contact CSB® sales engineers.

▊FLEXMOV® High-flexible Cable Finder V1.0 is based on a large amount of test data from CSB® laboratories and combined analysis and calculation of cable materials and structural characteristics. You can find suitable cables by selecting sheath materials, cable application parameters and application environment options, and combined with the cable core wire and shielding requirements, the system will output an adapted flexible cable.

▊Since the system's simulation calculation analysis based on theoretical data may not fully meet the input parameters, data verification has certain limitations; CSB® recommends that flexible cables need to be tested and verified again on the equipment to fully meet the actual use requirements.

▊The output data information of the FLEXMOV® high-flexible cable finder is only for reference in design selection and cannot be used as the basis for final cable compliance determination; if you have any questions, please contact CSB® sales engineers.

CSB-LIN® Linear guide rails & Screw nuts designed with the maintenance-free sliding conponents. All sliding parts are made of wear-resistant material CSB-EPB®. resistant to dust, anti-corrosion and low noise.

moreDURAMOV® cable chains are made of high strength and anti-wear plastics, The cable chains are used in a variety of motion modes and strokes. DURAMOV® cable chains can carry FLEXMOV® flexible cables and energy hoses...

moreCSB automation technology is based on maintenance free sliding friction as a motion pair to achieve maintenance free, low noise, longer service life, and lightweight design of automation module components and robots...