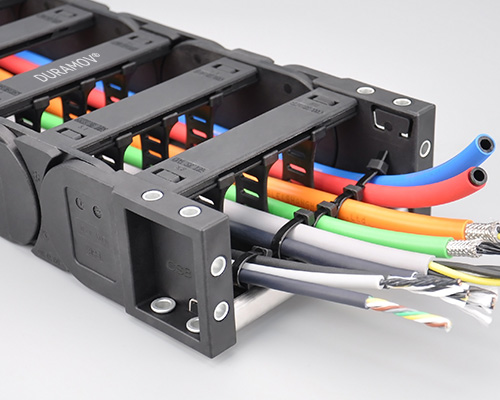

C03 high load cable carriers combines all the advantages of the previous versions and is the best DURAMOV® carriers in the product range. C03 cable carriers is stronger whilst having the same or even smaller dimensions than previous versions. You can increase the service life of your application with C03 cable carriers whilst reducing cost.

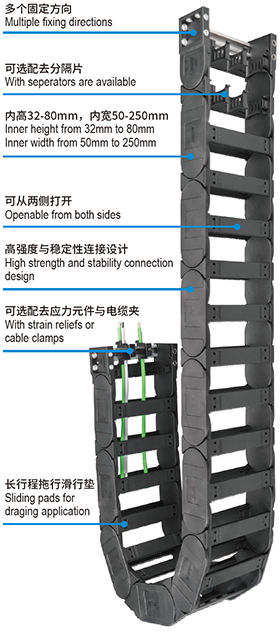

● Attachment from any side with mounting brackets

● Long service life: lateral sliding surfaces design

● High strength and stable: due to undercut design, high fill weight available

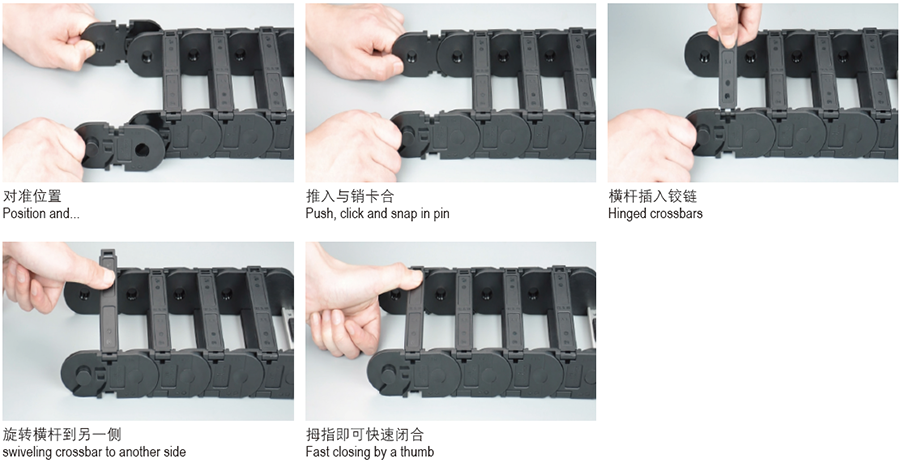

● Fast assembly: easy assembly with quick lock crossbars

● Inner height:32 mm

● Inner width:50-200 mm

● Bend radius:63-300 mm

● Link pitch:56 mm

● Inner height:42 mm

● Inner width:50-200 mm

● Bend radius:75-350 mm

● Link pitch:67 mm

● Inner height:56 mm

● Inner width:100-300 mm

● Bend radius:135-500 mm

● Link pitch:91 mm

● Inner height:80 mm

● Inner width:100-300 mm

● Bend radius:150-500 mm

● Link pitch:111 mm

C03 high load cable carriers combines all the advantages

of the previous versions and is the best DURAMOV®

carriers in the product range. C03 cable carriers is stronger

whilst having the same or even smaller dimensions than

previous versions. You can increase the service life of

your application with C03 cable carriers whilst reducing cost.

Openable from both sides

Openable from both sides

Flammability Class UL94 HB

Flammability Class UL94 HB

CE certification

CE certification

RoHS certification

RoHS certification

| High load cable carriers | Part No. | Inner width Bi [mm] | Outer width Ba [mm] | Inner height Hi [mm] | Outer height Ha [mm] | Bend radius R [mm] | Unsupported length [m] |

| C03.32 | 50-200 | 73-223 | 32 | 54 | 63-300 | ≤3.0 | |

| C03.42 | 50-200 | 76-226 | 42 | 64 | 75-350 | ≤4.2 |

| C03.56 | 100-300 | 134-334 | 56 | 84 | 135-400 | ≤5.0 |

| C03.80 | 100-300 | 148-298 | 80 | 108 | 150-500 | ≤5.8 |

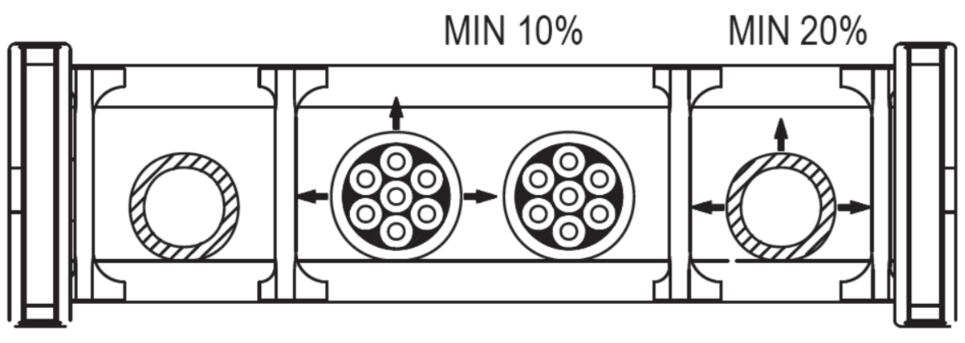

In order to ensure that the chain is functioning properly and to avoid damage to the cables or hoses, the following principles must be observed when laying cables or hoses:

| ▊ This minimum clearance would be 10% for electrical round cables, 20% for hydraulic hoses. |

| ▊ In order to reduce the possible friction, avoid pipes with different skin materials such as cables or hoses.(eg: cable and hydraulic hoses) |

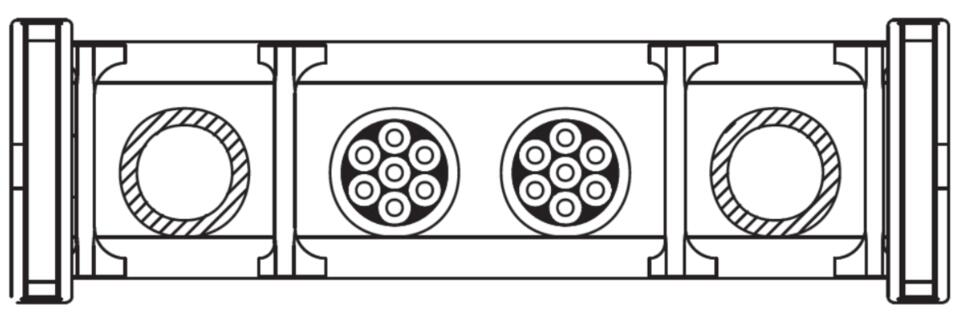

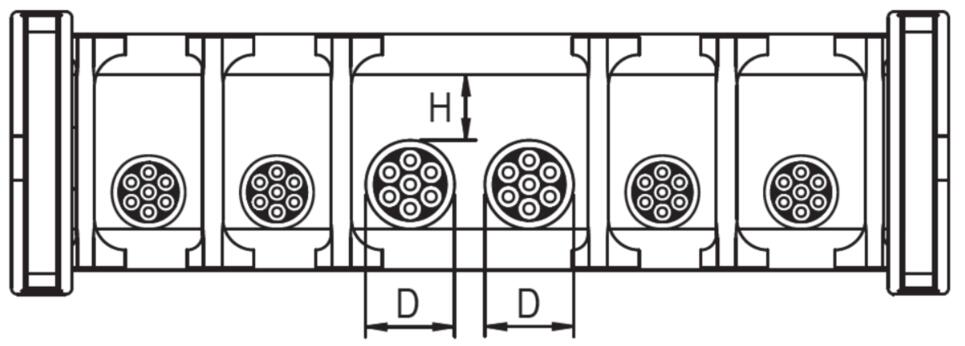

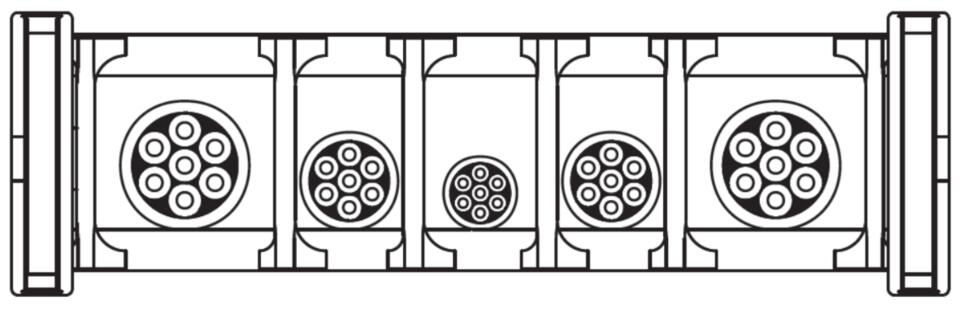

| ▊ In applications where multiple cables and hoses are used, in order to avoid mutual friction between them, it is preferable to place them in a suitable separate space and separate them from each other with a spacer. If there are no conditions to achieve, make sure there is enough space between them to avoid mutual friction (H<D). |

| ▊ The cables or hoses are laid in a symmetrical manner according to their diameter and weight. The largest and heaviest cables are placed on the outside of the section and the small and light cables are placed on the inside. |

● The separator separates inside space of the chain to protect cables, oil hoses, gas hoses, etc.

● Separator with high strength, can be firmly fitted in carriers

more● Aluminum alloy, surface anodized

● The tiewrap elements can move within the guide slot

more● Used for C03 cable chains long stroke protection

● Made of friction-optimized wear-resistant composite plastic

● Rugged and durable, extend the life of the cable carrier

more● Use with vertical separators to arrange the space in the cable chain in layers up and down.

● The vertical separators can move freely along the horizontal direction.

BL bellows is suitable for use in general mechanical applications, The good anti-freezing ability and self-extinguishing properties can be used in automotive industries. The bellows keep high impact resistance in ...

more● Lift plats & cranes

● General mechanical

● Handling machines

● Refrigeration engineering

● Construction machinery

● Woodworking machines

● Stone cutting machines

● Long travel and sliding applications

CSB conducts approximately 10 million DURAMOV® cable chain endurance tests at 68 laboratory stations and more than 30 application stations every year. The cable chain test laboratory includes different installation and application tests: short-stroke unsupported installation, vertical hanging, vertical standing, side-mounted and long-stroke sliding tests in outdoor natural climates; The cable chain application station tests include: Application tests of C02 cable chains on machining centers, Application tests of C02 and C06 cable chains on grabbing manipulators or robots, Application tests of C03 cable chains on long-stroke manipulators, Application tests of micro cable chains such as C01 and C31 on high-frequency motion devices...

DURAMOV® cable chains undergo durability testing for robot applications and long-stroke drag and slide applications in a precision shaft production workshop in Anhui, China. C02.25 cable chain is mainly used in the Z-axis and Y-axis of the manipulator, and C03.42 cable chain is mainly used in the long-stroke moving area of the manipulator; the lateral travel about 25 meters, and it performs more than 2,000 cycles every day, and the grabbing movements over 4000 cycles; DURAMOV® cable chain ensures 24-hour trouble-free operation of the automatic production line...

▊DURAMOV® Cable Chain Finder[V1.1] is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations filler and installation data by entering parameters such as cables, gas tubes, oil tubes and installation data, The system will analyze your design data and finally output the adaptation cable chains.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the cable chains must be tested again to verify whether it meets the actual use requirements.

▊DURAMOV® Cable Chain Finder output data information is only for design reference, and can not be used as the final standard for determining the cable chains conformity, If you have any questions, please contact CSB® sales engineers.

▊FLEXMOV® High-flexible Cable Finder V1.0 is based on a large amount of test data from CSB® laboratories and combined analysis and calculation of cable materials and structural characteristics. You can find suitable cables by selecting sheath materials, cable application parameters and application environment options, and combined with the cable core wire and shielding requirements, the system will output an adapted flexible cable.

▊Since the system's simulation calculation analysis based on theoretical data may not fully meet the input parameters, data verification has certain limitations; CSB® recommends that flexible cables need to be tested and verified again on the equipment to fully meet the actual use requirements.

▊The output data information of the FLEXMOV® high-flexible cable finder is only for reference in design selection and cannot be used as the basis for final cable compliance determination; if you have any questions, please contact CSB® sales engineers.

High flexible cables are designed for highly bending and continuous motion applications and used for cable chains, robots, auto-drive systems, etc ...

moreElastic connection and small pitch for low-noise, smooth running, openable along the both sides

Inner height: 28mm

Inner width: 30 to 60mm

Openable along inner or outer radius from both sides, large pin/bore and crossbar with high locking force

Inner height: 18 to 45mm

Inner width: 38 to 175mm