●Closed design

●High precision similar to preloaded ball bearing

●Standard liner materials TEFPLAS®

●Anodized aluminum adapter

●Maintenance-free and low noise

●Operation temperature ±200℃

●Closed and long design

●Standard liner materials TEFPLAS® B

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and long design

●Lower starting friction liner materials TEFPLAS® G

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and long design

●FDA grade liner materials TEFPLAS® E

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and short design

●Standard liner materials TEFPLAS® B

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and short design

●Lower starting friction liner materials TEFPLAS® G

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and short design

●FDA grade liner materials TEFPLAS® E

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and and self-aligning design

●Standard liner materials TEFPLAS® B

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and and self-aligning design

●Lower starting friction liner materials TEFPLAS® G

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed and and self-aligning design

●FDA grade liner materials TEFPLAS® E

●Anodized aluminum adapter

●Maintenance-free and low noise

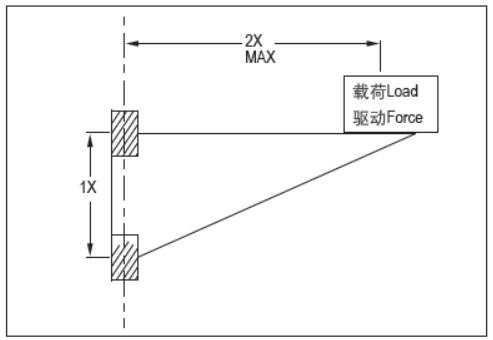

●Maximum 2:1 ratio

●1x =bearing separation on same shaft

●2x =distance from shaft to load or force

●CAUTION: uneven motion or even system blockage will occur if the 2:1 ratio is exceeded !

This principle is NOT load dependent! It is NOT due to edge loading. It is also NOT dependent on the driving force used! The greater the distance between the drive and guide bearings, the higher the degree of wear and required drive force.

There may be other factors that add to the braking effect, but the coefficient of friction is the main cause.

NOTE: The Rule(2:1) is based on the static friction value of 0.25 theoretically, However, Additional lubrication can help to drop friction and extend the 2:1 ratio.

If you have any questions on design and/or assembly, please contact our application engineers.

AS: Hard anodized aluminum shaft, the best shaft for LIN linear bearings; CS: Hard-chromed steel shaft, the effective-cost shaft; ES: 304 Stainless steel shaft, the best for chemical liquid; Shaft end processing service...

more

3085

3302

3140

▊CSB-LIN® Plastic Linear Bearings Finder[V2.0] including LIN plastic linear bearings and LINP precision linear bearings. The system is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations bearing data by entering parameters such as bearing load, speed, temperature and position information, The system will output bearing adaptation data and min. driving force.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the bearing must be tested again to verify whether it meets the actual use requirements.

▊CSB-LIN® Plastic Linear Bearings Finder output data information is only for design reference, and can not be used as the final standard for determining the bearing material conformity, If you have any questions, please contact CSB® sales engineers.

● Closed design linear bearings

● Standard long and short design

● Self-aligning design

●Opening design for supported shafts

●Standard liner materials TEFPLAS®

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed design with round flange

●Standard liner materials TEFPLAS®

●Anodized aluminum adapter

●Maintenance-free and low noise

●Closed design with housing

●Standard liner materials TEFPLAS®

●Anodized aluminum adapter

●Maintenance-free and low noise