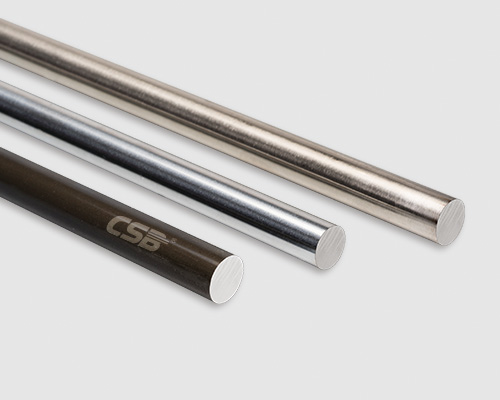

● AS: Hard anodized aluminum shaft, the best shaft for LIN linear bearings

● CS: Hard-chromed steel shaft, the effective-cost shaft

● ES: 304 Stainless steel shaft, the best for chemical liquid

● Shaft end processing service is available

● Material: AL 6061/6060

● Surface: hard anodized

● Straightness: EN 754-3

● Solid and hollow shafts are available

● Cost-effective steel shafts

● Also completely supported and assembled with standard aluminium support

● C45 steel, hard-chromed

● High corrosion-resistance

● Also completely supported and assembled with standard aluminium support

● Good solution for the applications under wet environment

● Aluminum material and low weight

● Anodized surface

● With locking screw, easy to install

CSB-LIN® maintenance free plastic linear bearings. Low noise operation is suitable for continuously applications under the extremely dusty environment. It is washable by the clean detergent of the food machine …

moreCSB-LIN®P precision linear bearings with higher load carrying capacity and extremely low operating noise. The liners are made of TEFPLAS® for maintenance-free and low friction coefficient, operation temperature ±200℃...

more▊CSB-LIN® Plastic Linear Bearings Finder[V2.0] including LIN plastic linear bearings and LINP precision linear bearings. The system is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations bearing data by entering parameters such as bearing load, speed, temperature and position information, The system will output bearing adaptation data and min. driving force.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the bearing must be tested again to verify whether it meets the actual use requirements.

▊CSB-LIN® Plastic Linear Bearings Finder output data information is only for design reference, and can not be used as the final standard for determining the bearing material conformity, If you have any questions, please contact CSB® sales engineers.

Compact and low high design support;

Standard design support;

3 materials shaft: Hard anodized aluminum shaft, Hardchromed steel shaft, 304 Stainless steel shaft;

moreAluminum alloy material, Hard anodized surface of sliding; Maintenance-free linear slide guides providing virtually limitless design freedom; Lubrication-free and dirt-resistant...

moreSmall installation height between 6 and 12 mm;

Lightweight;

Numerous carriage options – also with pretension;

Maintenance-free, self lubricating;

moreEfficient and durable CSB-LMS® high helix threads;

Self-locking trapezoidal standard threads;

Maintenance-free, dry operation;

Corrosion resistant、Resistant to dirt and Low-noise;

moreThe coupling connects the drive shaft of the axis to the Motor, An elastic polymer insert in the centre of the coupling transfers the motor torque, This damping element compensates for radial and axial clearance...

more