● Screw drives are machine elements that convert rotary motion into linear motion. CSB-LMS® screw drives are always based on CSB-EPB® self-lubricating plastic nuts, thus enabling long-lasting operation without external lubrication.

● Efficient and durable CSB-LMS® high helix threads;

● Self-locking trapezoidal standard threads;

● Maintenance-free, dry operation;

● Corrosion resistant、Resistant to dirt and Low-noise;

● Thread: right- or left-hand

● Available materials: C45 steel /304 stainless steel

● Length and machining according to customer drawing

● Thread: right- or left-hand

● Available materials: 304 stainless steel

● Length and machining according to customer drawing

● Self lubricating and lower wear

● Best coefficient of friction

● Chemical resistant

● Dust resistant and quit running

● Self lubricating and lower wear

● Easy installation with bolts

● Best coefficient of friction

● Chemical resistant

● Self lubricating and lower wear

● High efficiency drive

● Easy installation with bolts

● Best coefficient of friction

● Self lubricating and lower wear

● Best coefficient of friction

● Chemical resistant

● Dust resistant and quit running

● Self lubricating and lower wear

● Save space and Easy installation with bolts

● Best coefficient of friction

● Chemical resistant

● Special design nuts for LMS linear motion system

● Self lubricating and lower wear

● Best coefficient of friction

● Chemical resistant

● Special design nuts for LMS linear motion system

● Self lubricating and lower wear

● Best coefficient of friction

● Chemical resistant

● Lubricant- and maintenance-free

● Quick connection

● Transmission of high rotation speed

● Low friction

● Ready to install in the screw

● Custom solutions for lead screw support

● Can absorb even high axial forces

● Clamping rings made from coated aluminum

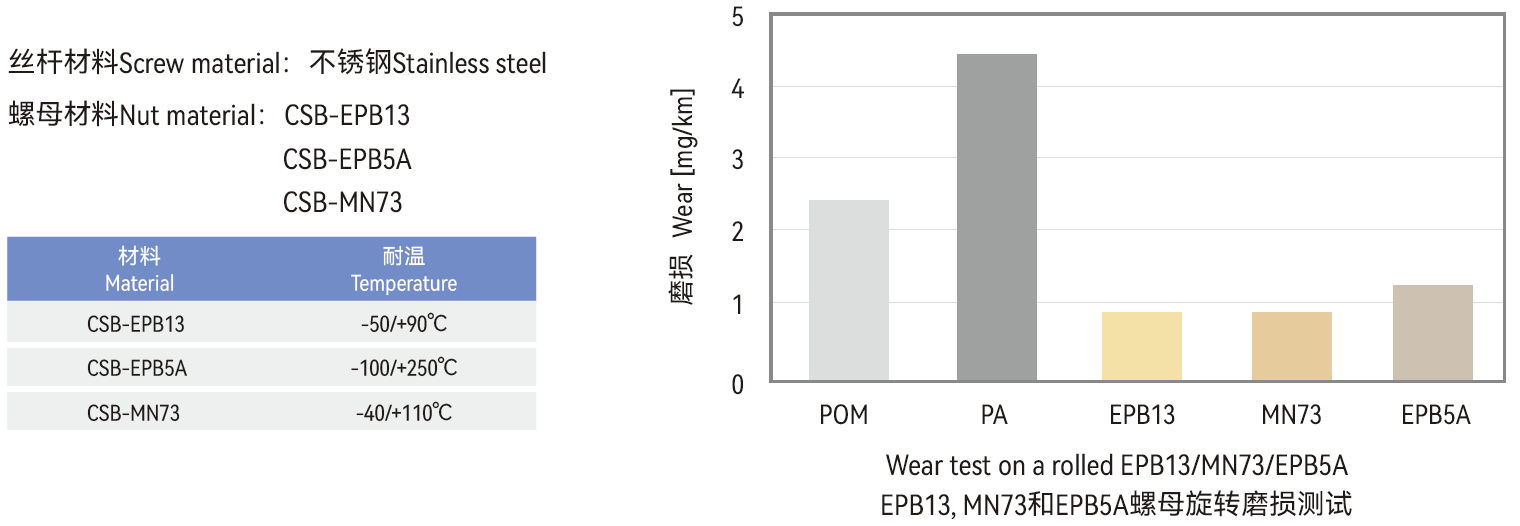

CSB-LIN® lead screw drives are manufactured in accordance with DIN 103. CSB-LIN® high-helix lead screws have high moving speeds been obtained at low rotational speeds. CSB-LIN® high-helix lead screws has made this possible by using a high-helix pitch. CSB-LIN® lead screws are made of stainless steel and are formed by the old-rolling process. They are coupled with high wear-resistant material CSB-EPB13 nuts designs. For higher loads or special applications, CSB-EPB5A may be used for the nuts.

Please note that the temperature also has an effect on the clearance of the nut, as well as the maximum load capacity. When the application is

exposed to particularly low or high temperatures, we recommend testing the suitability of the lead screw nuts in this specific case by a practical test.

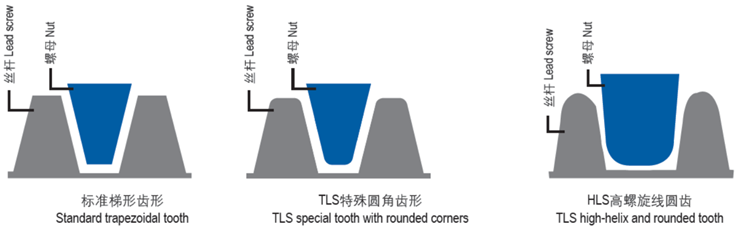

Due to a flatter thread angle in CSB-LIN® high- helix lead screws and nuts, the drive force is efficiently converted into a translational motion, Compared with standard trapezoidal thread angle, this means a lower power loss. Due to the radius tooth design, The thread moving without lubrication, low noise and vibration dampening.

Radial loads or torque brought to bear upon the nut result in overload of individual contact surfaces, thus seriously affecting the service life of the lead screw assembly. Therefore it is important to properly mount the screw and to comply with all relevant form and positional tolerances.

The required drive torque of the threaded nut is obtained from the axial load, the lead screw pitch, the coefficient of surface friction of lead screw unit and the lead screw bearing. At high speeds, the acceleration torque must be taken into account, which may cause increased start torque depending on the installation. Dirt, dust and the surface or the condition of the lead screw can increase the drive torque. However, lubrication can temporarily reduce the required drive forces.

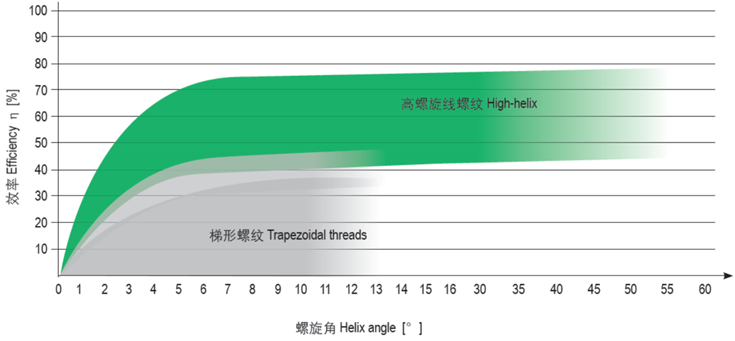

Efficiency is the ratio between the output and input power rating. CSB-LIN® lead screw nuts are characterised by lowfriction values, resulting in high efficiencies.

Single start trapezoidal lead screw nuts achieve efficiencies between 20 and 48% under dry running conditions. High helix lead screw nuts achieve efficiencies between 50 and 80% under dry running conditions. Even though CSB-LIN® lead screw nuts were developed for completely dry running conditions, lubrication can help to additionally increase efficiency.

Trapezoidal lead screw nuts from CSB-EPB13 must be used for applications in humid environments, especially for wet applications. These material are characterised by very low moisture absorption.

Dirt with the use of the maintenance-free CSB-EPB® materials for lead screw nut production, CSB-LIN® lead screw drives feature completely dryrunning operation. Due to the deliberate avoidance of lubricants, the adhesion of soft particles such as dust and fibres is reduced. When compared to conventional, lubricated materials, it is common to see significant improvements in the service life in contaminated environments. However, in environments with significant contamination and hard particles, such as metal chips or granite dust, the lead screw should be covered.

Noise can generally occur with the use of lead screw drives. In particular, long lead screws and long travel distances can cause self-induced vibrations in the systems. Due to their good sliding characteristics, lead screw nuts from the tribologically optimised CSB-EPB® materials tend to develop less noise than conventional plastics or metallic materials, such as bronze or brass.

DURAPLAS® self-lubricated plastic semi-finished products available service for the customer special requirement of uncommon bearings. It is possible for the mold cost saving and improves the delivery time...

moreCSB-LIN® lead screws and nuts designed with the flatter thread angle, the drive force is efficiently converted into a translational motion, Compared with standard trapezoidal thread angle, this means a lower power loss. Due to the radius tooth design, The thread moving without lubrication, low noise and vibration dampening. DURAFILM® coating technology provides a new solution for improving the efficiency of standard stainless steel screw drives at low temperatures...

AS: Hard anodized aluminum shaft, the best shaft for LIN linear bearings; CS: Hard-chromed steel shaft, the effective-cost shaft; ES: 304 Stainless steel shaft, the best for chemical liquid; Shaft end processing service...

moreCompact and low high design support;

Standard design support;

3 materials shaft: Hard anodized aluminum shaft, Hardchromed steel shaft, 304 Stainless steel shaft;

moreAluminum alloy material, Hard anodized surface of sliding; Maintenance-free linear slide guides providing virtually limitless design freedom; Lubrication-free and dirt-resistant...

moreSmall installation height between 6 and 12 mm;

Lightweight;

Numerous carriage options – also with pretension;

Maintenance-free, self lubricating;

moreThe coupling connects the drive shaft of the axis to the Motor, An elastic polymer insert in the centre of the coupling transfers the motor torque, This damping element compensates for radial and axial clearance...

more