● The dimensions are the same as the ball bearing guides

● Made of hard anodized surface of aluminum alloy

● Resistant dust

● Quiet operation

● Lightweight design

● Small installation width from 09 to 12 mm

● The dimensions are the same as the ball bearing guides

● Made of hard anodized surface of aluminum alloy

● Maintenance-free with TRC roller carragies

● Fitted standard liners EPB13

● Maintenance-free, dry-running

● Fast assembly and light weight

● For TR linear guide rails

● Sliding layer material: TEFPLAS® B

● Operation temperature ±200℃

● Max. continuous running speed 1.5m/s

● Maintenance-free, dry-running

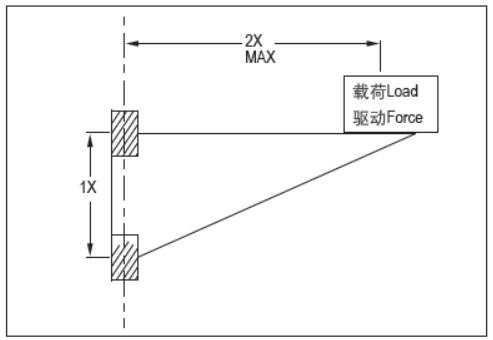

● Maximum 2:1 ratio

● 1x = bearing separation on same shaft

● 2x = distance from shaft to load or force

● CAUTION: uneven motion or even system blockage will occur if the 2:1 ratio is exceeded !

This principle is NOT load dependent! It is NOT due to edge loading. It is also NOT dependent on the driving force used! The greater the distance between the drive and guide bearings, the higher the degree of wear and required drive force.

There may be other factors that add to the braking effect, but the coefficient of friction is the main cause.

● NOTE: The Rule(2:1) is based on the static friction value of 0.25 theoretically, However, Additional lubrication can help to drop friction and extend the 2:1 ratio.

AS: Hard anodized aluminum shaft, the best shaft for LIN linear bearings; CS: Hard-chromed steel shaft, the effective-cost shaft; ES: 304 Stainless steel shaft, the best for chemical liquid; Shaft end processing service...

moreCompact and low high design support;

Standard design support;

3 materials shaft: Hard anodized aluminum shaft, Hardchromed steel shaft, 304 Stainless steel shaft;

moreSmall installation height between 6 and 12 mm;

Lightweight;

Numerous carriage options – also with pretension;

Maintenance-free, self lubricating;

moreEfficient and durable CSB-LMS® high helix threads;

Self-locking trapezoidal standard threads;

Maintenance-free, dry operation;

Corrosion resistant、Resistant to dirt and Low-noise;

moreThe coupling connects the drive shaft of the axis to the Motor, An elastic polymer insert in the centre of the coupling transfers the motor torque, This damping element compensates for radial and axial clearance...

more