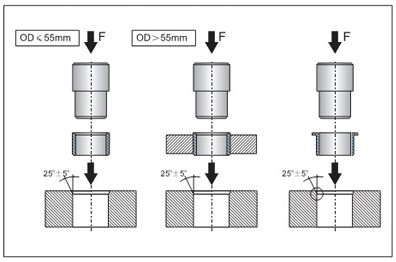

The outer diameters of CSB-EPB® plastic plain bearings are designed with positive tolerances, which are interference fit with the standard H7 mounting hole. Sufficient interference press-in force ensures that the bearing will not fall out of the housing during operation. CSB-EPB® plastic plain bearings are designed with external chamfer on one end as guiding during installation to prevent the bearings from being damaged during the press-fitting process. It is recommended that the housing hole should have a chamfer of 1~2.5mm at 25 degrees at the press-in end to avoid damage to the outer surface of the bearing, which also ensures that a standard tolerance value for the bearings after press-fitting.

No additional adhesive is required for the installation of CSB-EPB® plastic plain bearings. If the temperature of working conditions exceeds the allowed operating temperature of the bearings and needs to use special adhesives to strengthen the bearings, please contact CSB application technical engineer: tech@csb-ep.com.

The inner hole tolerance standard is E10 tolerance after the CSB-EPB® plastic plain bearings is pressed into the housing,, and the matching shaft tolerance is h9. CSB engineering plastic bearings do not require additional lubricant. If you must use additional lubricant, please contact CSB application technical engineer: tech@csb-ep.com.