● PUR outer jacket

● Shielded

● Flame-retardant

● Notch-resistant

● UV-resistance

● Oil-resistant and coolant-resistant

● Hydrolysis and microbe-resistant

● Temperature: -50/+70℃

| Code | ||

| Core wire | ||

| Outer diameter | mm | |

|

||

|

|

Bus type | Profibus |

|

|

Number of cores and conductor nominal cross-section [mm] | (2×0.2.5)C |

|

|

Colour code | 2×0.2.5:red,green |

|

|

Grounding wire | - |

|

|

Outer diameter [mm] | 8.5 |

|

|

Copper index [kg/km] | 25 |

|

|

Weight [kg/km] | 75 |

|

|

Drive technology system | - |

|

|

Min. bending radius[mm], Moving in cable carriers(factor) | 12.5×d |

|

|

Min. bending radius[mm], Moving in cable carriers | 106.25 |

|

|

Min. bending radius[mm], Fexible moving(factor) | 10×d |

|

|

Min. bending radius[mm], Fexible moving | 85 |

|

|

Min. bending radius[mm], Fixed installation(factor) | 7×d |

|

|

Min. bending radius[mm], Fixed installation | 59.5 |

|

|

Temperature[℃], Moving in cable carriers | -20 up to +70 |

|

|

Temperature[℃], Fexible moving | -40 up to +70 |

|

|

Temperature[℃], Fixed installation | -50 up to +70 |

|

|

v max.[m/s], unsupported | 3 |

|

|

v max.[m/s], gliding | 2 |

|

|

a max.[m/s²] | 30 |

|

|

Travel distance[m] | Unsupported travels and up to 20 m for gliding applications |

|

|

Torsion[°] | - |

|

|

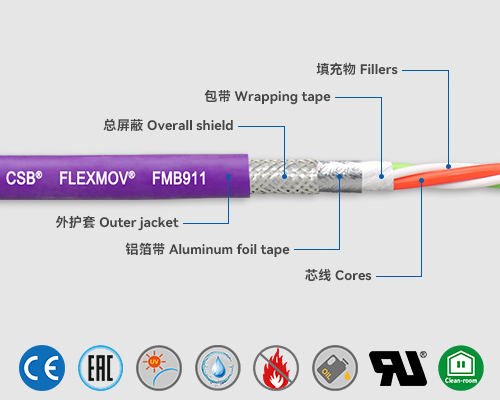

Conductor | Conductor consisting of bare copper wires (according to DIN EN 60228). |

|

|

Conductor insulation | According to bus specification. |

|

|

Conductor construction | According to bus specification. |

|

|

Color code | According to bus specification. |

|

|

Element shield foil | - |

|

|

Element shield | - |

|

|

Element jacket | - |

|

|

Intermediate layer | polymer tape tied over the outer layer |

|

|

Inner jacket | - |

|

|

Overall shield foil | Aluminum foil taping over the outer layer |

|

|

Overall shield | Extremely bending-resistant braiding made of tinned copper wires. Coverage linear approx. 70 %, optical approx. 90 % |

|

|

Outer jacket | Low-adhesion mixture on the basis of PUR, especially abrasion-resistant and highly flexible, adapted to suit the requirements in cable carriers. |

|

|

Jacket color | Red lilac RAL4001 |

|

|

Characteristic wave impedance approx. [Ω] | 150 |

|

|

Nominal voltage [V] | 50 |

|

|

Test voltage [V] | 500 |

|

|

UV-resistance | Medium |

|

|

Hydrolysis-resistance | High |

|

|

Cold-resistant [℃] | -50 |

|

|

Oil resistance | Oil-resistant (following IEC60811-404, tested by SGS), bio-oil-resistant (following VDMA24568, tested by SGS) |

|

|

Halogen-free | Following IEC60754 |

|

|

Flame resistance | According to IEC 60332-1-2、VW-1、FT1 |

|

|

Silicone-free | Free from silicone which can affect paint adhesion |

|

|

REACH | Accordding to the regulation (EC) No. 1907/2006 (REACH) |

|

|

Lead-free | Following 2015/863/EU (RoHS-II Tested by SGS) |

|

|

EAC | Certificate No.KG 417/043.CN.02.00249 |

|

|

Cleanroom | Following ISO 14644-1 |

|

|

CE | Following 2014/35/EU |

|

|

UL | Following UL20233, 80℃, 300V |

▊FLEXMOV® FMB911 Flexible bus cable service life

| Double strokes | 5 million times | 7.5 million times | 10 million times |

Temperature,from/to [℃] | R min. [factor x d] | R min. [factor x d] | R min. [factor x d] |

| -20 / -10 | 15 | 16 | 17 |

| -10 / +60 | 12.5 | 13.5 | 14.5 |

| +60 / +70 | 15 | 16 | 17 |

***According to the FLEXMOV® guarantee.

DURAMOV® cable chains are made of high strength and anti-wear plastics, The cable chains are used in a variety of motion modes and strokes. DURAMOV® cable chains can carry FLEXMOV® flexible cables and energy hoses...

more● Can be integrated with C03 series connectors and C-profiles

● A compact modular design of easy installation, less space, cost-effective

more● Can be integrated with C03 series connectors and C-profiles

● A compact modular design of easy installation, less space, cost-effective

more● Can be integrated with C03 series connectors and C-profiles

● A compact modular design of easy installation, less space, cost-effective

moreBL bellows is suitable for use in general mechanical applications, The good anti-freezing ability and self-extinguishing properties can be used in automotive industries. The bellows keep high impact resistance in ...

more▊FLEXMOV® High-flexible Cable Finder V1.0 is based on a large amount of test data from CSB® laboratories and combined analysis and calculation of cable materials and structural characteristics. You can find suitable cables by selecting sheath materials, cable application parameters and application environment options, and combined with the cable core wire and shielding requirements, the system will output an adapted flexible cable.

▊Since the system's simulation calculation analysis based on theoretical data may not fully meet the input parameters, data verification has certain limitations; CSB® recommends that flexible cables need to be tested and verified again on the equipment to fully meet the actual use requirements.

▊The output data information of the FLEXMOV® high-flexible cable finder is only for reference in design selection and cannot be used as the basis for final cable compliance determination; if you have any questions, please contact CSB® sales engineers.

● PVC outer jacket

● Flame-retardant

● Oil-resistant

● UV-resistance

● Temperature: -15/+70℃

● TPE outer jacket

● Flame-retardant

● UV-resistance

● Hydrolysis and microbe-resistant

● Temperature: -50/+70℃