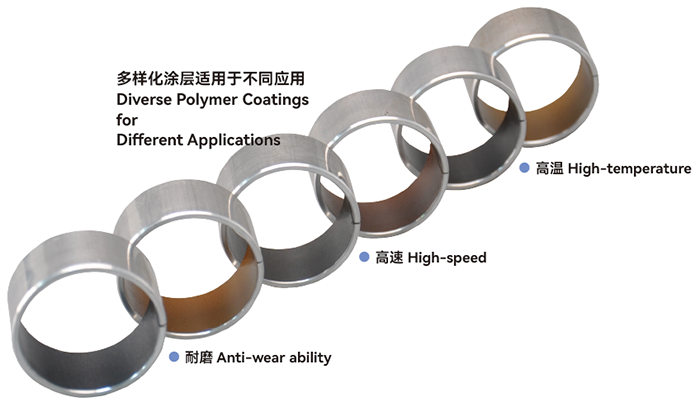

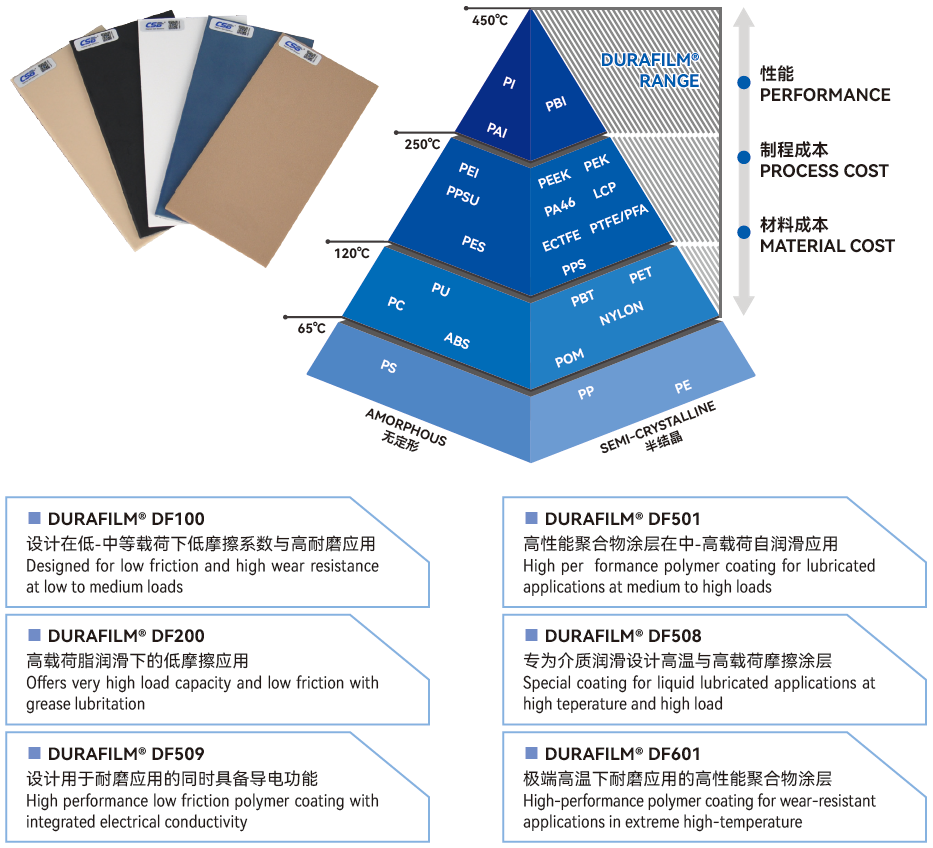

DURAFILM® polymer coatings combine thermoplastic and thermosetting composite layers, providing superior lubrication performance for components operating in extreme environments. They offer excellent wear-resistant layers on friction surfaces while delivering anti-rust and anti-corrosion protection for metal parts. Based on application requirements, we have developed specialized highperformance coatings tailored for low friction coefficients, high loads, high temperatures, conductivity, and other demanding conditions.

| Coating Type | DF100 | DF200 | DF501 | DF508 | DF509 | DF601 | |

Color | Dark gray | Dark gray | Dark gray | Charcoal gray | Black | Brown | |

Usage | dry | Excellent | Excellent | Excellent | Fair | Fair | Excellent |

| oil lubricated | Good | Good | Excellent | Excellent | Good | Excellent | |

| grease lubricated | Fair | Excellent | Good | Excellent | Good | Excellent | |

| water lubricated | Poor | Poor | Fair | Excellent | Good | Fair | |

| Mechanical properties at high temperature | Poor | Excellent | Excellent | Excellent | Excellent | Excellent | |

| Chemical resistance | Excellent | Good | Excellent | Excellent | Excellent | Excellent | |

Smoke/toxicity | Fair | Good | Excellent | Excellent | Excellent | Excellent | |

Radiation resistance | Fair | Excellent | Excellent | Excellent | Excellent | Excellent | |

Outgassing | Fair | Excellent | Excellent | Excellent | Excellent | Excellent | |

Release properties | Excellent | Fair | Excellent | Excellent | Good | Excellent | |

| Long-term application temperature [℃] | +260 | +250 | +260 | +260 | +260 | +380 | |

| Short-temm application temperature [℃] | +280 | +315 | +315 | +315 | +315 | +400 | |

| Lowest application temperature [℃] | -196 | -100 | -100 | -100 | -100 | -100 | |

| Typical properties | Low coefficient of friction Dry friction High corrosion resistance High temperature 260°C | High-load, low-speed applications Dry friction Grease lubrication PFAS-free High temperature 250°C | Dry friction Oil lubrication Water lubrication High load High temperature 260°C | Grease lubrication Water lubrication High load Corrosion resistant PFAS-free High temperature 260°C | Electrical conductivity ≤103 Corrosion resistant PFAS-free High temperature 260°C | Low friction coefficient High strength Corrosion resistant High temperature 380°C | |

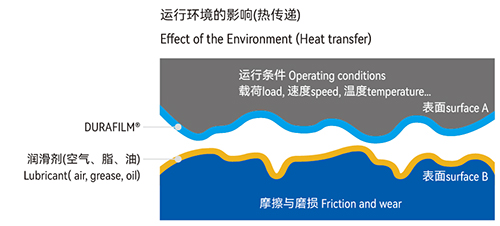

The polymer coating contains solid lubricant particles dispersed within a resin matrix. The volume concentration and selection of lubricant types are critical to achieving optimal lubrication and corrosion resistance. The liquid coating is applied through various processes, ensuring the base resin adheres firmly to the substrate. During operation, the friction-reducing materials in the coating are released, forming a stable lubricating interface between friction pairs.

When looking for ways to improve system performance, engineers must consider a number of factors including:

■ Lubrication

■ Heat transfer and effect of the operating environment

■ Two interacting frictional surfaces

■ Coating R&DPossessing in-house formulation design and customization capabilities for polymer coatings to precisely regulate surface properties. | ■ Chemical and Corrosion ProtectionExhibits exceptional chemical stability and corrosion resistance, forming an inert material barrier between contact surfaces to extend component lifespan. | |

■ Design SimplificationEnables simplified design in complex-shaped surfaces inaccessible to traditional bearings, reducing component quantity and simplifying assembly processes. | ■ Self-LubricationIncorporate solid lubricants to deliver self-lubricity that can help reduce and sometimes eliminate the need for additional lubrication in machine parts. | |

■ Broad Substrate CompatibilityCompatible with metallic substrates such as steel, stainless steel, and aluminum (with potential extension to polymeric and composite substrates too). | ■ Hard Chrome ReplacementHard chrome plating is being phased out due to toxicity and high costs. DURAFILM® polymer coatings offer an eco-friendly alternative with superior wear and corrosion resistance, delivering a sustainable upgrade for industrial surface treatment. |

▊DURAFILM® Coating surface selection

CSB recommends coating both opposing surfaces of the friction pair as the optimal solution. However, considering cost factors in general applications, coating only one friction surface can also meet performance requirements. Balancing process and cost considerations, we suggest that thin-walled bushings can be manufactured by rolling coated sheets into shape. For bushings with an inner diameter smaller than 20mm or a length-to-diameter ratio greater than 2, we recommend applying coating to the mating shaft surface. For irregularly shaped mating surfaces, priority should be given to coating the component surface where the external face serves as the friction surface.

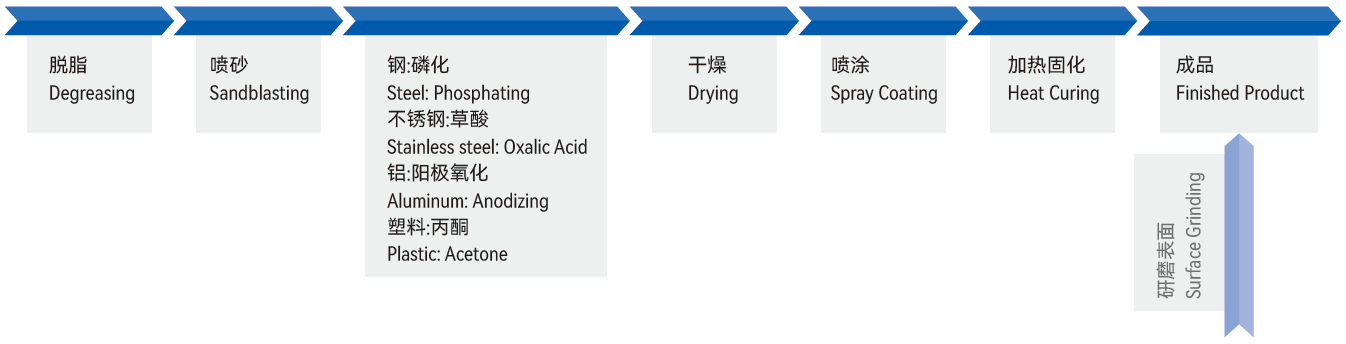

To ensure the effectiveness and longevity of DURAFILM polymer coatings, strict adherence to the correct application process is essential. Surface pretreatment is crucial and may include degreasing, sandblasting, phosphating, anodizing, pickling, or other treatments, depending on the substrate material.

After the pretreated components are dried, the polymer coating is applied using suitable methods, followed by drying and curing to ensure strong adhesion between the lubricant-rich coating and the substrate. For applications requiring high surface precision, surface grinding may be added. However, polishing or grinding is not recommended for coatings on components already lubricated with oil or grease, as it may compromise performance.

As equipment manufacturers face increasing design diversity and complexity of components, traditional self-lubricating sintered composite bearings and wear-resistant composite plastics processed via injection molding or extrusion can no longer meet industrial demands. With over 20 years of expertise in self-lubricating materials and products, CSB developed DURAFILM® polymer coating technology to address the limitations of conventional manufacturing methods in developing high-performance wear-resistant components. DURAFILM® polymer coatings reduce friction, extend wear life, lower system noise, and enhance corrosion resistance.

CSB delivers complete friction coating services through DURAFILM® polymer coating technology, combining tribological and design expertise to provide customized coating solutions tailored to your specific application requirements.

■ Bushing、slide plate、shaft friction surface

■ Medical equipment

■ Transmission chain

■ Solenoid valve

■ Metal gear

■ Trapezoidal lead screw

CSB-EPB® Plastic plain bearings use high-performance plastics as the raw material, and filled high-strength fibers and special solid lubricants by the polymer compound technology to improve the anti-wear resistance...

moreDURARUB® backing material is high strength glass fiber with epoxy resin and the lubricating layer is PTFE filament and high strength fiber. The special structure performs an outstanding anti-wear feature and low friction…

moreCSB-SRB® slewing ring bearings are made of self-lubricating materials as the sliding units,Smooth operation and no noise, High-speed operation and long life, Operation temperature ±200℃…

moreHigh-performance wear-resistant materials serve as sliding layers combined with high-strength fiber-reinforced load-bearing layers; DURARUB® materials are suitable for applications with consistently high static and ...

moreTEFPLAS® is designed for high speed applications with anti-wear sliding layer, TEFPLAS® composite materials are self-lubricating and maintenance-free, suitable for higher speeds and low friction...

moreCSB-LIN®P precision linear bearings with higher load carrying capacity and extremely low operating noise. The liners are made of TEFPLAS® for maintenance-free and low friction coefficient, operation temperature ±200℃...

more● Continuous working temperature: -20/+120℃;

● Low coefficients of friction;

● Available underwater;

● Easy to cut;