● Continuous working temperature: -20/+120℃

● Low coefficients of friction

● Available underwater

● Easy to cut

● Standard thickness 0.50mm

● Individual widths from 20 to 300 mm

● Available tapes without adhesive back

● FDA grade

● Low coefficients of friction

● Available underwater

● Continuous working temperature: -20/+80℃

● FDA grade

● Available high speed applications

● UV aging resistance

● Continuous working temperature: -20/+120℃

● Low coefficients of friction

● Higher hardness

● UV aging resistance

● Continuous working temperature: -20/+90℃

● Low coefficients of friction

● Available underwater

● UV aging resistance

● Continuous working temperature: -20/+80℃

● Low coefficients of friction

● Excellent wear resistance

● Universal chemical resistance

● Continuous working temperature: -100/+250℃

▊Technical data

| Material | Dry friction coefficient [u] | Max. static load [Mpa] | Max. dynamic load [Mpa] | Max. PV [N/mm2xm/s] | Max. Speed [m/s] | Operation temperature* [℃] | ||

| Continuous | Intermittent | Long-term | Short-term | |||||

| TRIBOTAPER® 11 | 0.05-0.15 | 15 | 5 | 0.25 | 0.3 | 0.5 | -20/+80 | -50/+100 |

| TRIBOTAPER® 17 | 0.05-0.12 | 12 | 6 | 0.40 | 1.0 | 2.0 | -20/+120 | -50/+180 |

| TRIBOTAPER® 70 | 0.10-0.25 | 30 | 13 | 0.30 | 0.3 | 0.5 | -20/+90 | -50/+120 |

| TRIBOTAPER® 81 | 0.05-0.15 | 15 | 5 | 0.25 | 0.3 | 0.5 | -20/+80 | -50/+100 |

*Operation temperature of standard tape with adhesive back

Please contact us for the operation temperature of the tape without adhesive back

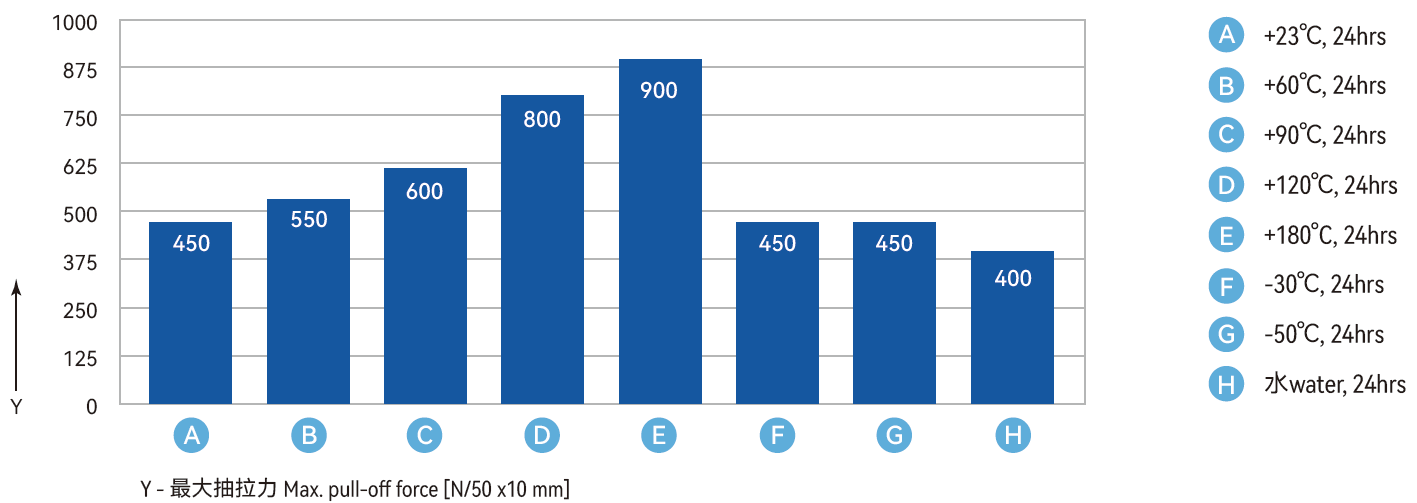

▊Adhesion strength

180°pull-off test after various exposure conditions

*Note:

The test data is based on typical values measured at 23°C after TRIBOTAPE® was bonded to SPCC Ra0.8 steel plates and exposed to various conditions. This is not a maximum or minimum value. The adhesion strength of TRIBOTAPE® anti-wear tapes will decrease over time or with alternating changes in the use environment; CSB is not liable for the defects of an adhesive system based on anti-wear tapes.

CSB-EPB® Plastic plain bearings use high-performance plastics as the raw material, and filled high-strength fibers and special solid lubricants by the polymer compound technology to improve the anti-wear resistance...

moreCSB-LIN® maintenance free plastic linear bearings. Low noise operation is suitable for continuously applications under the extremely dusty environment. It is washable by the clean detergent of the food machine …

moreCSB-LIN® Linear guide rails & Screw nuts designed with the maintenance-free sliding conponents. All sliding parts are made of wear-resistant material CSB-EPB®. resistant to dust, anti-corrosion and low noise.

moreHigh-performance wear-resistant materials serve as sliding layers combined with high-strength fiber-reinforced load-bearing layers; DURARUB® materials are suitable for applications with consistently high static and ...

moreDURAPLAS® self-lubricated plastic semi-finished products available service for the customer special requirement of uncommon bearings. It is possible for the mold cost saving and improves the delivery time...

moreDURAMOV® cable chains are made of high strength and anti-wear plastics, The cable chains are used in a variety of motion modes and strokes. DURAMOV® cable chains can carry FLEXMOV® flexible cables and energy hoses...

moreTEFPLAS® is designed for high speed applications with anti-wear sliding layer, TEFPLAS® composite materials are self-lubricating and maintenance-free, suitable for higher speeds and low friction...

more