● A self-lubricating material with low water absorbtion. Good wear resistance will be maintained when used with soft shaft and hard shaft combined

● Continuous working temperature: -40℃/+100℃

● Maintenance-free dry operation

● High load requirement

● Suitable for working in humid environment

Material properties | Standard | Unit | CSB-EPB18 |

General properties | |||

Color | - | - | Yellow |

Density | ISO1183 | g/cm3 | 1.40 |

Max. moisture absorption, 50%RH | ISO62 | % | 0.3 |

Max. water absorption | ISO62 | % | 0.5 |

Coefficient of sliding friction(steel) | ITS025 | µ | 0.05-0.18 |

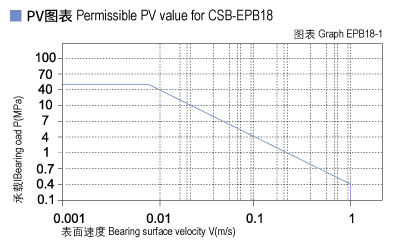

Max. PV value | ITS026 | N/mm2×m/s | 0.40 |

Mechanical properties | |||

Flexural modulus | ISO178 | MPa | 2700 |

Flexural strength | ISO178 | MPa | 65 |

Max. static load | ITS027 | MPa | 50 |

Max. dynamic load | ITS028 | MPa | 21 |

Shore hardness | ISO868 | D | 75 |

Physical and thermal properties | |||

Long-term application temperature | ITS029 | ℃ | +100 |

Short-term application temperature | ITS029 | ℃ | +160 |

Lowest application temperature | ITS029 | ℃ | -40 |

Thermal conductivity | ISO22007 | W/m/K | 0.25 |

Coefficient of thermal expansion | ISO11359 | K-1×10-5 | 8 |

Flammability | UL94 | Class | HB |

Electrical properties | |||

Volume resistance | IEC60093 | Ω·cm | >1012 |

Surface resistance | IEC60093 | Ω | >1011 |

*ITS: CSB company's internal test standards. **Test temperatures are 23℃ unless otherwise stated.

The max PV value of the CSB-EPB18 plastic bearings is 0.4N/mm2×m/s which determines the load capacity of bearing is inversely proportional to the speed. Please refer to the chart for more detailed information (Graph EPB18-1).

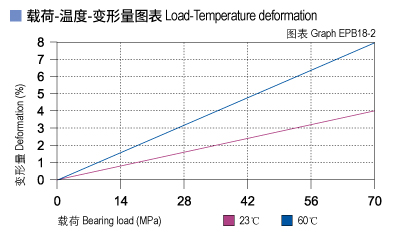

CSB-EPB18 allows the Max static load of 50Mpa, The max compressive deformation rate under the max load is listed in Graph EPB18-2, The actual load capacity of bearing is slightly less than 50Mpa, The bearing load is variable against the speed and temperature, Fast speed (Vmax: 1.0m/s) results into higher temperature (Tmax: 100℃) which decreases the load capacity of the bearing. Please refer to the Graph EPB18-3 for such variation.

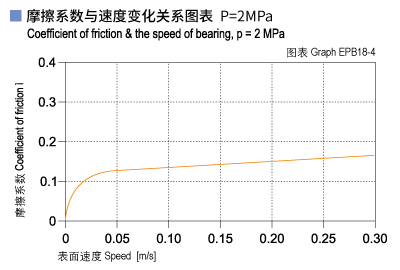

Graph EPB18-4 shows that as the same as most of the slide bearing materials, the friction factor of CSB-EPB18 is increasing along with the rotation speed under a certain loading while as shown in figure EPB18-5, it is decreased along with the increasing of loading when the operation speed is stable. From figure EPB18-6, it is found that the most suitable shaft roughness is Ra0.2 to Ra0.6. Smoother shaft or rougher shaft may result into friction factor increasing.

| CSB-EPB18 | Dry | Grease | Oil | Water |

| Friction coef. μ | 0.05~0.18 | 0.09 | 0.04 | 0.04 |

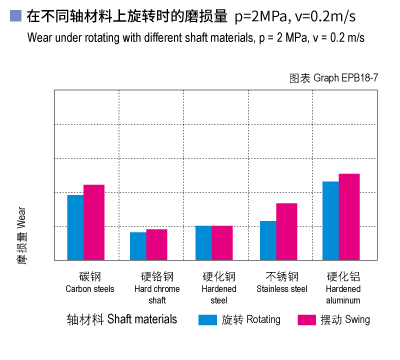

Graph EPB18-7 and EPB18-8 shows the wearing is considerably affected by the shaft materials. Heat-treated steel shaft and carbon steel shaft is good for this bearing material. Graph EPB18-7 tells that CSB-EPB18 is suitable for hardened chrome steel and hardened steel shaft in rotation operation or oscillation operation.

CSB-EPB18 is good at chemical resistance against weak acidic medium and various kinds of lubricants.

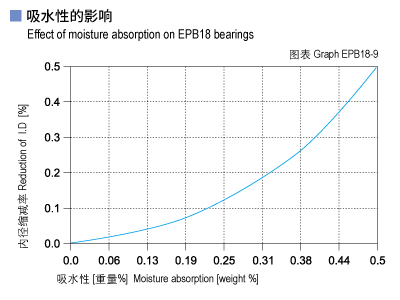

The moisture absorption of CSB-EPB18 plastic plain bearings is 0.3% in standard atmosphere. The max. water absorption is 0.5% in water . These values are very low, CSB-EPB18 plastic palin bearings is very well suited for used in wet applications.

Disintegration could be possible for the material CSB-EPB18 after long period of exposing under the UV ray and therefore the performance of the material will be reduced.

CSB-EPB18 Tolerances after pressfit

Diameter [mm] | CSB-EPB18 E10 [mm] | Housing H7 [mm] | Shaft h9 [mm] |

>0~3 | +0.014~+0.054 | 0~+0.010 | 0~-0.025 |

>3~6 | +0.020~+0.068 | 0~+0.012 | 0~-0.030 |

>6~10 | +0.025~+0.083 | 0~+0.015 | 0~-0.036 |

>10~18 | +0.032~+0.102 | 0~+0.018 | 0~-0.043 |

>18~30 | +0.040~+0.124 | 0~+0.021 | 0~-0.052 |

>30~50 | +0.050~+0.150 | 0~+0.025 | 0~-0.062 |

>50~80 | +0.060~+0.180 | 0~+0.030 | 0~-0.074 |

>80~120 | +0.072~+0.212 | 0~+0.035 | 0~-0.087 |

>120~180 | +0.085~+0.245 | 0~+0.040 | 0~-0.100 |

▊CSB-EPB® Plastic Bearings Finder[V2.0] is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations material data by entering parameters such as bearing load, speed, and temperature, and finally output material adaptation data.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the bearing must be tested again to verify whether it meets the actual use requirements.

▊CSB-EPB® Plastic Bearings Finder output data information is only for design reference, and can not be used as the final standard for determining the bearing material conformity, If you have any questions, please contact CSB® sales engineers.

▊CSB-SFP® Semi-finished Products Finder[V2.0] is based on the analysis and calculation of a large number of test data in CSB® laboratory. You can calculations material data by entering parameters such as bearing load, speed, and temperature, and finally output material adaptation data.

▊Because the system calculate and analyze based on lab data, it can't exactly meet the ractual use requirements absolutly. The system data verification has certain limitations; CSB® recommends that the products must be tested again to verify whether it meets the actual use requirements.

▊CSB-SFP® Semi-finished Products Finder output data information is only for design reference, and can not be used as the final standard for determining the bearing material conformity, If you have any questions, please contact CSB® sales engineers.

| Medium | EPB18 bearings resistance |

| Alcohol | Resistant |

| Hydrocarbons | Not resistant |

| Greases. oils | Resistant |

| Fuels | Resistant |

| Diluted acids | Conditionally resistant |

| Strong acids | Not resistant |

| Diluted alkalis | Not resistant |

| Strong alkalis | Not resistant |

Please select bearing material and medium...

▊CSB® bearing material chemical resistance data is a comparison test result of the CSB chemistry laboratory using laboratory specimens or similar chemicals at room temperature 23 ℃, without considering the impact of other temperatures and chemical medium mixtures on the chemical resistance of CSB® bearing materials ; Therefore, this data can only act as a reference. CSB® recommends that the chemical resistance of actual parts should be tested under application conditions and verify the suitability of the bearings.

For soft shafts,

Excellent wear resistance ,

Operation temperatures up to +200 ℃,

Good resistance to chemicals.

moreThe solution of middle to low load application and economic effective requirement. It is also one of the low water absorbing materials.

moreWear resistance material with high strength and low water absorbtion feature. The dimensions will be remain stable even in humidity environment. Continuous working temperature: -40℃/+130℃

moreLow friction and good wear resistance for high temperature applications. The excellent chemical resistance of the material ensures athe applications for high temperature and high chemical erosion applications.

more